Polishing powders have become a popular material in metal surface treatment. They are commonly used to make grinding wheels for polishing metal or used in blasting machines. Polishing powders offer numerous benefits and deliver high efficiency in the polishing process.

1. Learn about types of polishing powders

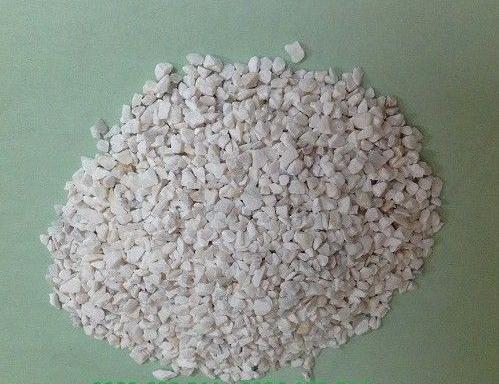

Polishing powder includes materials such as limestone powder, calcium carbonate (CaCO₃) powder, and ultra-fine white stone powder. These powders have a wide range of applications across various industries. They act as fillers to enhance product properties such as glossiness, coverage, smoothness, adhesion, weight, and shaping ability. In addition, they improve impact resistance, increase dispersion efficiency, serve as a base for color expression, facilitate processing, and help reduce production costs.

In metal surface treatment and polishing processes, polishing powder, also known as polishing sand, is a specialized abrasive material used for finishing metal surfaces. Currently, polishing powder is widely used and available in various particle sizes, typically ranging from #60, #80, #150, #240, #320, #400 to #600. Each particle size is suitable for a different type of surface finishing process.

Fine-grained sand is generally used for metal surface polishing. Due to its small particle size, it can easily smooth and shine the surface through friction and contact. In contrast, coarse-grained sand is commonly used for deburring or smoothing rough metal surfaces.

2. Polishing powder with many useful applications

Polishing powder is used to make grinding wheels. Using polishing powder combined with glue and coconut fiber wheels will create grinding and polishing wheels. The commonly used types of glue are cement glue, buffalo hide glue, two-component glue, and synthetic glue. When applying a layer of glue on the coconut fiber wheel, rolling it through the polishing powder, and drying it, a grinding wheel is formed. With each different particle size of the polishing powder, the grinding wheel will be used for smoothing or polishing metal surfaces.

Another application of polishing powder is its use with blasting machines in metal surface treatment. The workpiece that needs polishing is placed on a conveyor belt and then moved into the blasting chamber of the sandblasting machine. Here, the nozzles move vertically and horizontally along the conveyor, blasting sand at high pressure. The sand particles, under the pressure of the nozzles, impact the metal surface. After one side of the product is treated, the sandblasting machine flips the product and processes the remaining side. The polishing chamber is enclosed, and after contacting the product, the sand particles fall into a slot on the conveyor, then are drawn up by the nozzles and reused, minimizing material loss.

Thus, polishing powder has many different applications and is widely used in metal surface treatment.

For customers who wish to purchase machines, materials, or use LEKAR Group’s metal polishing services, please contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11 Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch – Lai Xa Industrial Cluster, Hoai Duc, Hanoi: 02437 646469.

Southern Branch – Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City: 02873 033386.