General Introduction

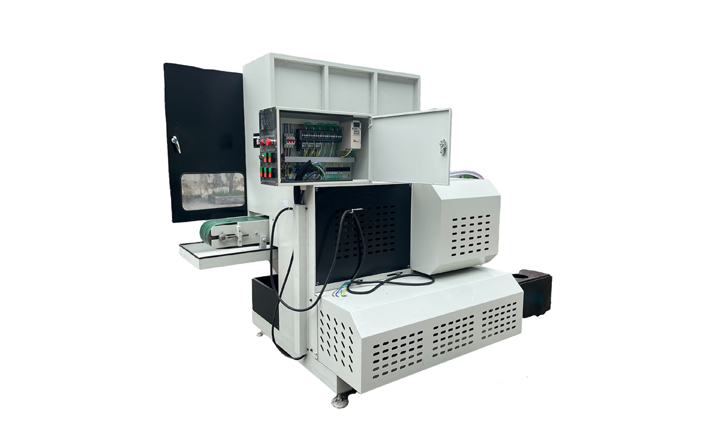

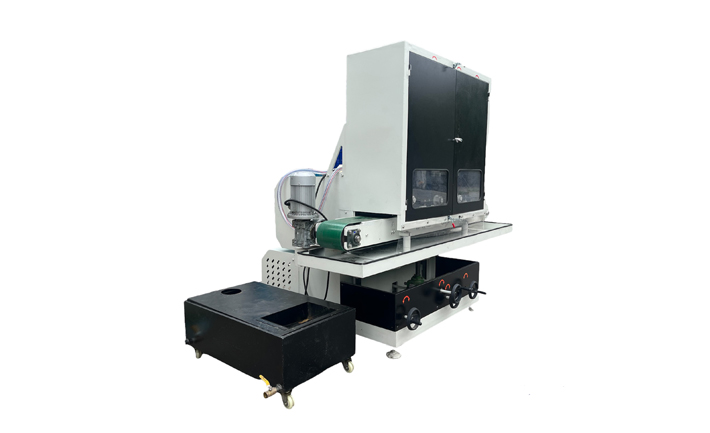

This machine is mainly used for smoothing, creating a matte hairline finish, or polishing accessories with flat sheet surfaces, bars, or box shaped workpieces.

Bar shaped products are processed using a two head wet grinding machine.

SPEC

| Model | 1D1N-R-13 | 2D1N-R-17 | 3D1N-R-22 |

|---|---|---|---|

|

|

2 | 3 | 3 |

| Main motor power (kW) | 9,5 | 13,5 | 17,5 |

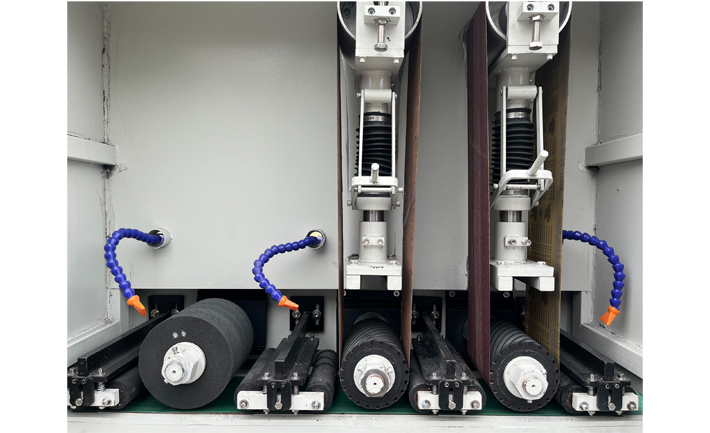

| Abrasive belt head speed (rpm) | 2000 | 2000 | 2000 |

| Non-woven polishing head speed (rpm) | 1440 | 1440 | 1440 |

| Abrasive belt size (mm) | 200 × 2100 | 200 × 2100 | 200 × 2100 |

| Non-woven wheel size (mm) | 250 × 200 | 250 × 200 | 250 × 200 |

| Worktable specifications | Chiều rộng 200mm; Chiều cao nâng hạ 0–100mm | ||

| Overall machine dimensions (mm) | 2000 × 1800 × 2000 | 2300 × 1800 × 2000 | 2500 × 1800 × 2000 |

Note: Dimensional tolerance ±50 mm. Technical specifications can be adjusted according to customer requirements.

Multi head flat surface scratch machine (2 sanding belt grinding units, 1 non-woven wheel grinding unit)

Outstanding features of the Three head wet belt grinding Machine

– The three head wet belt grinding machine is a newly developed piece of equipment, transferred from countries with advanced and developed industrial technologies.

– The device can process the surfaces of all types of metals such as iron, copper, aluminum, and stainless steel in flat, sheet, box, and bar forms used in the production of furniture, counters, shelves, sports equipment, posts, and more.

– The operation of the three head wet grinding machine is very simple, with an intelligent operating mode that does not require highly skilled operators. The machine runs smoothly and is easy to maintain and service.

– The three head wet belt grinding machine offers many superior features not only in surface treatment but also in terms of economic value. Using this machine significantly reduces labor intensity and labor costs while ensuring both product quality and output.

– Especially, the three head wet grinding machine uses water during the defect removal process. This not only cools the workpiece but also cleans it, prevents dust, and ensures safety for both the environment and the workers.

***See more: High Technology Grinding Machine

For more detailed consultation about the three head wet belt grinding machine and other products and services from LEKAR, customers are kindly requested to contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Headquarters: Unit 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi, Vietnam

Northern Branch – Lai Xa Industrial Cluster, Hoai Duc Commune, Hanoi, Vietnam: 02437 646 469

Southern Branch – Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City, Vietnam: 02873 033 3866.