Sandblasting, also known as abrasive grain blasting, is a surface finishing process that involves using a motorized machine – typically an air compressor – to propel abrasive particles at high pressure onto a surface. When the abrasive grain attacks the surface, it creates a smoother and more uniform texture. In this post, you’ll learn more about the surface finishing process using a sandblasting machine.

If customers still have hesitation about the product, register now to receive free consultation and metal surface treatment technology testing: https://bit.ly/309aR3m

Overview

Sand has high abrasive properties, and taking advantage of this, sandblasting machines were developed. After sandblasting, the surface of the product becomes smoother. For example, sandpaper contains many individual sand grains. When rubbed against a surface, the sand removes some of the top layer material, creating a smoother texture. Sandblasting works in a similar way, except it uses sand under high pressure.

How does it work?

The first step in the process is to pour sand into the sandblasting machine. The sandblasting machine has a top chamber for sand input. It is then connected to a regular air compressor, and when activated, the air compressor pushes the sand through a handheld nozzle. Depending on the settings, the sand pressure can range from 50 to 130 pounds per inch.

The sand is then “blown” onto the surface, and due to its abrasive nature, it can create a smoother surface. For example, concrete is often sandblasted. After the concrete is poured and allowed to dry, it is treated by sandblasting. This process removes some of the excess material on the concrete, making it smoother.

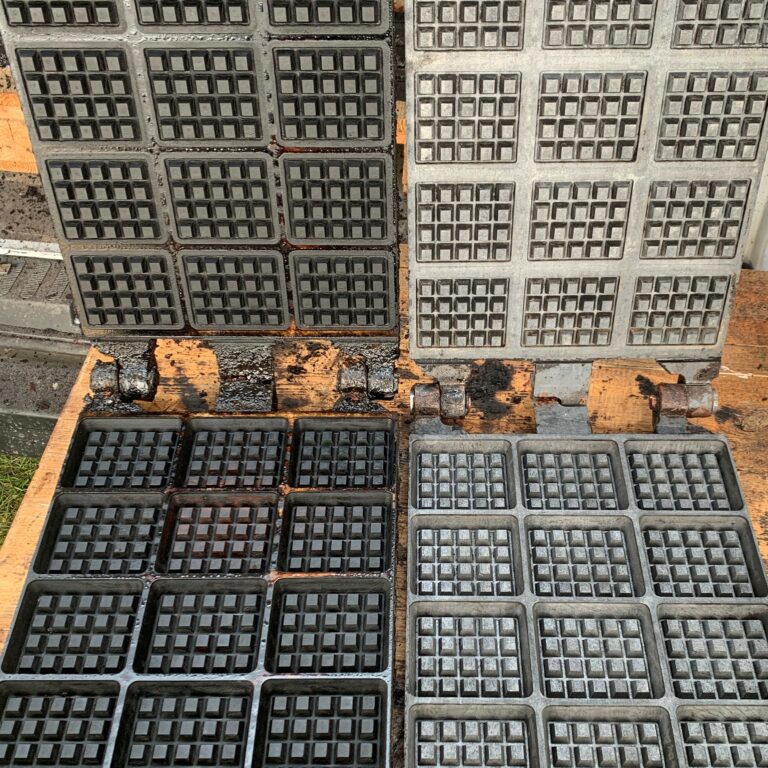

Sandblasting creates surface roughness on concrete.

Shot blasting is the use of steel beads or steel shot to blast onto the surface of a workpiece. The use of steel beads is often combined with a shot blasting chamber to recover the blasting material. This is a closed cleaning system that automatically recovers the sand, helping to extend the blasting time and prevent environmental pollution.

What is the difference between sandblasting and shotblasting?

Both methods use compressed air to create a pressurized stream that propels abrasive materials such as steel shot, steel grit, or silica sand. These abrasives are blasted onto the surface of the workpiece to clean, remove rust, create roughness, and prepare the surface before painting.

In sandblasting, sand is pushed onto the surface. In contrast, shotblasting uses spherical particles – small metal balls – that are shot onto the surface. These particles are usually made from stainless steel, copper, aluminum, or zinc. All of these metals are harder than sand, making the blasting process even more effective than using sand in terms of cleaning and surface treatment.

Sand Blasting Machine for Cleaning Molds

👉 “Explore the types of sandblasting and shot blasting machines provided by LEKAR:”

https://danhbongkimloai.com.vn/may-phun-phun-bi-phun-cat-va-cac-loai-hat-phun-cp34.html

Where to buy a Sandblasting machine?

With advantages such as high cleaning capacity and low abrasive consumption, the automatic sand blasting machine is a reliable solution trusted by many companies across the country.

With over 10 years of experience in surface finishing, LEKAR supplies imported blasting machines from leading industrial countries in the region such as Thailand and China – including automatic sand blasting machines that effectively meet various usage needs.

In addition, LEKAR also provides custom metal processing services, as well as maintenance and warranty for polishing machines. At LEKAR, business owners are offered modern metal surface treatment solutions at the most cost-efficient pricing.

For more detailed consultation on sand blasting machines or other equipment and consumables from LEKAR Group, please contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: Unit No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc Commune, Hanoi. Tel: 02437 646469.

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386.

Website: danhbongkimloai.com.vn | lekar.vn