Deburring media is a crucial material used to remove all sharp edges and burrs from metal surfaces after mechanical processing.

1. What is Burr (Bavia)?

After stamping or punching processes, metal products often have sharp and rough edges. These leftover sharp metal fragments are called burrs. Removing burrs is essential for improving the product’s aesthetics and achieving a smooth, polished surface. Today, many advanced tools and technologies are available for metal surface treatment and polishing. These include deburring media, polishing stones, and deburring machines, which significantly enhance processing efficiency and final product quality.

2. Introduction to deburring media

Deburring media is made from various materials such as ceramic, plastic, etc., with different sizes and shapes to suit each type of metal product.

Currently, there are many types of deburring media on the market. Although they have the same function, these media vary in size and origin. When purchasing, customers often pay attention to the following factors:

- Quality: Fast processing time, low media consumption

- Size: This is very important because in many cases, the metal parts to be treated have small corners or edges. If the media size has large deviations, it will be ineffective during processing.

Some types of deburring media:

– SRJ deburring media (Sphere rough): Coarse grinding media, suitable for initial deburring, used for products with soft surfaces, easy to process.

– RRR deburring media (Round pole rough): Coarse deburring media, specialized for removing large burrs, used for products with high hardness.

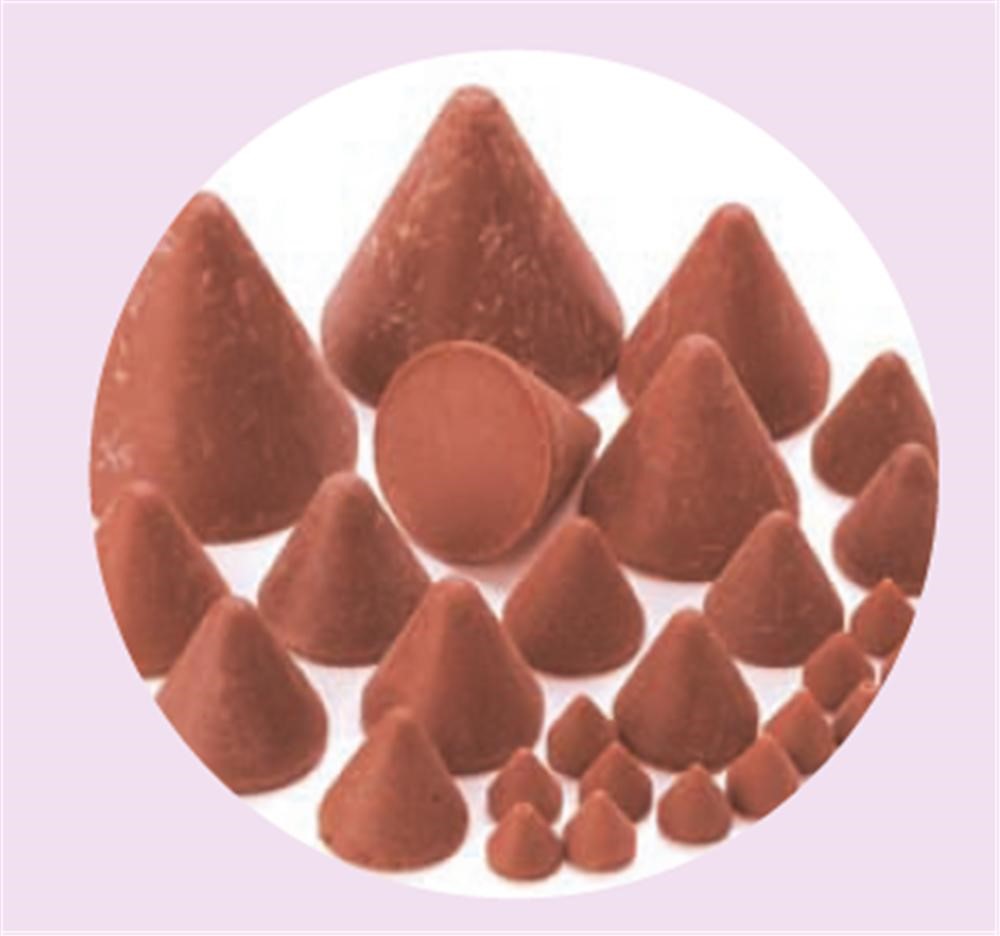

– CR deburring media (Cone rough): Plastic-based media, used for deburring, suitable for soft products with flat surfaces.

– CM (Cone medium), CR (Cone rough)…

Deburring Media (Cone Rough)

Outstanding features of deburring media:

– Creates a new surface for the product: burr-free, smooth, and bright

– Minimizes product deformation

– Simple to use: combined with polishing compounds and used with 3D vibratory polishing machines

– Low consumption rate, offering high economic efficiency

– Easy to store and environmentally friendly

How to select and use deburring media effectively

To choose the most suitable deburring media, you need to consider the material, size, and burr level of the product.If the product has many sharp edges and corners, you should select multi-edged media designed for burr removal. Choosing round media or fine polishing media for deburring purposes would be inappropriate and ineffective. In addition, selecting the right media size is also crucial, as it helps remove burrs more efficiently and in the shortest possible time.

When using polishing media in combination with a vibratory polishing machine and polishing compound, the deburring process will produce a smooth and shiny surface according to the specific requirements of each stage. The polishing compound functions to lubricate and soften the surface of the product, allowing friction and burr removal to happen more quickly. Additionally, the compound also reduces friction between abrasive particles, which slows down the consumption rate of the media, increasing overall efficiency.

In the deburring and surface smoothing process for steel, metal, and other materials, it is essential to use a centrifugal polishing machine or a vibratory polishing machine (also known as a 3D vibratory machine) in combination with polishing media, deburring media, and deburring compound.

Deburring time is also a critical factor. Excessive polishing time can lead to product deformation (excessive wear) and may result in the loss of mechanical properties of the material.

If you are looking to purchase machines, materials, or use LEKAR Group’s metal polishing services, please contact us at:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc, Hanoi | Tel: 02437 646 469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City | Tel: 02873 033 386

Website: danhbongkimloai.com.vn | lekar.vn