Metal processing and polishing are significant for most industries. Therefore, when choosing a metal processing facility in Hanoi for polishing services, customers need to consider the reputation and quality of the provider carefully.

1. Methods of metal polishing

Polishing is the final step in the metal processing workflow. It determines the aesthetics and the quality of the product by smoothing surface imperfections and creating a glossy finish. All metal products need to undergo polishing to meet the required standards before being sold on the market.

Metal polishing is the final stage in the metal processing workflow.

Metal polishing methods are divided into two main types:

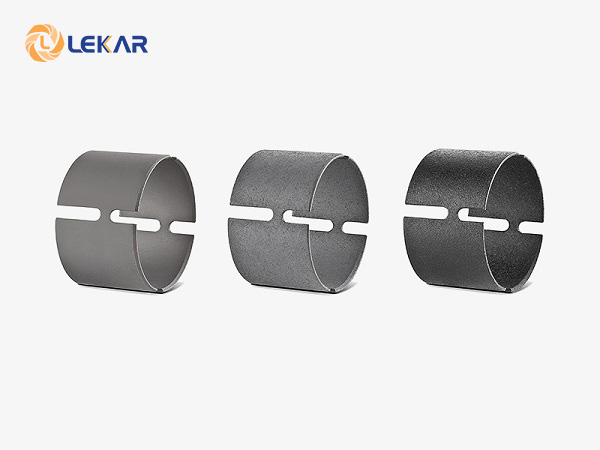

1. Polishing with vibratory machines or barrel finishing machines: This method is used for all three stages of polishing – rough, medium, and fine. It uses abrasive stones and chemical solutions to polish metal products.

2. Polishing with mechanical machines: This involves using mechanical grinders combined with abrasive materials such as felt pads, abrasive wheels, cloth wheels, coconut fiber wheels, and so on. This method is applied for polishing from deburring to mirror finishing.

Metal polishing is categorized into rough polishing, medium polishing, and fine polishing. Depending on the aesthetic requirements of the metal product, manufacturers need to choose the most suitable polishing metho

2. Products obtained after metal polishing

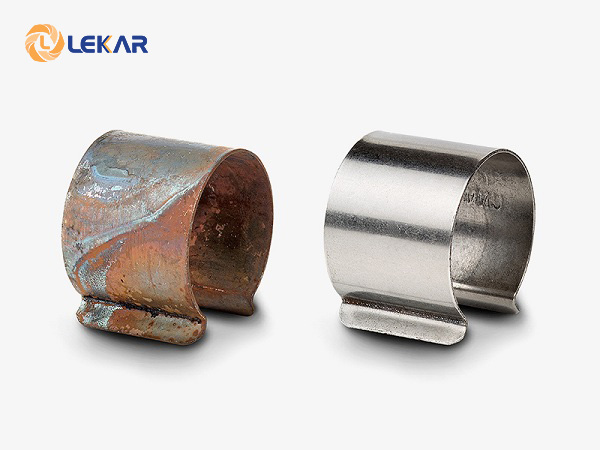

Raw metal products with sharp edges need to undergo deburring using a vibratory machine and a specialized deburring solution. The abrasive stones, solution, and the metal parts are mixed together, creating friction that smooths and rounds off the sharp edges. The resulting metal products have rounded, smooth edges, making them safe for handling.

Metal products with rough surfaces need to be ground using abrasive stones and specialized solutions in a vibratory polishing machine. The friction between the abrasive and the solution removes surface irregularities and protrusions. After this process, the metal products have a smooth surface with a relatively bright finish, making them suitable for painting or plating.

Metal products before and after polishing

For products that require both a smooth surface and a high gloss, all three polishing stages – rough, medium, and fine – need to be applied. Rough and medium polishing are performed using vibratory machines, abrasive stones, and polishing solutions, while fine polishing to achieve a mirror finish is done with mechanical grinders combined with cloth wheels and polishing wax. The metal products obtained after fine polishing are not only smooth but also highly reflective. These typically include items such as door handles, kitchen utensils (spoons, forks, bowls, plates, chopsticks, knife blades), sanitary equipment (shower heads, cup holders, mirror racks), and many other items.

Typically, manufacturers can either complete the polishing process in-house by purchasing machines, abrasive stones or media, and polishing solutions or wax, or they can send their products to reputable and experienced metal polishing service providers for professional support.

3. Reputable metal polishing service providers in Hanoi

With over 10 years of experience in supplying machinery and polishing materials, Lekar Group is currently one of the leading and most trusted companies in the metal polishing support industry in Vietnam. Through high-quality machines, materials, and dedicated technology transfer, Lekar has helped many businesses save time and costs in finishing metal products, while increasing both production capacity and product value.

Lekar Group provides a range of equipment including 3D vibratory machines, barrel finishing machines, mechanical grinders, as well as materials such as abrasive stones, polishing wax, solutions, wire brushes, abrasive belts, and cloth wheels to meet diverse metal polishing needs. Customers can be fully assured of product quality when working with Lekar Group. In addition to supplying machinery and materials, Lekar Group also offers professional metal polishing services for clients who require it.

Lekar Group – a reputable metal processing service provider in Hanoi with many years of industry experience

Affordable prices, high-quality products, and dedicated service have been the foundation of Lekar’s reputation and excellence for over 10 years. In addition to providing metal processing services in Hanoi, Lekar Group has expanded with branches in southern provinces to broaden its business reach and support businesses in achieving the most efficient metal polishing results.

Customers interested in metal polishing services or purchasing machinery and auxiliary materials are welcome to contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch – Lai Xa Industrial Cluster, Hoai Duc, Hanoi: 02437 646469.

Southern Branch – Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City: 02873 033386.