Top 3 Most Common Types of Blanks in Mechanical Processing and Popular Surface Treatments Today

What is a mechanical blank? What types does it include?

A mechanical blank is an indispensable element in mechanical processing (especially in precision mechanics). It consists of components that form a complete mechanical product with specific dimensions, designs, and shapes that have been pre-engineered.

Basically, there are three main types of mechanical blanks:

Casting blanks

Stamping (bending) blanks

Turning blanks

Casting blanks are produced through hot working methods – by melting metal and pouring it into molds that are shaped and sized according to design requirements.Casting blanks are typically categorized into two main types: sand casting blanks and die casting blanks.

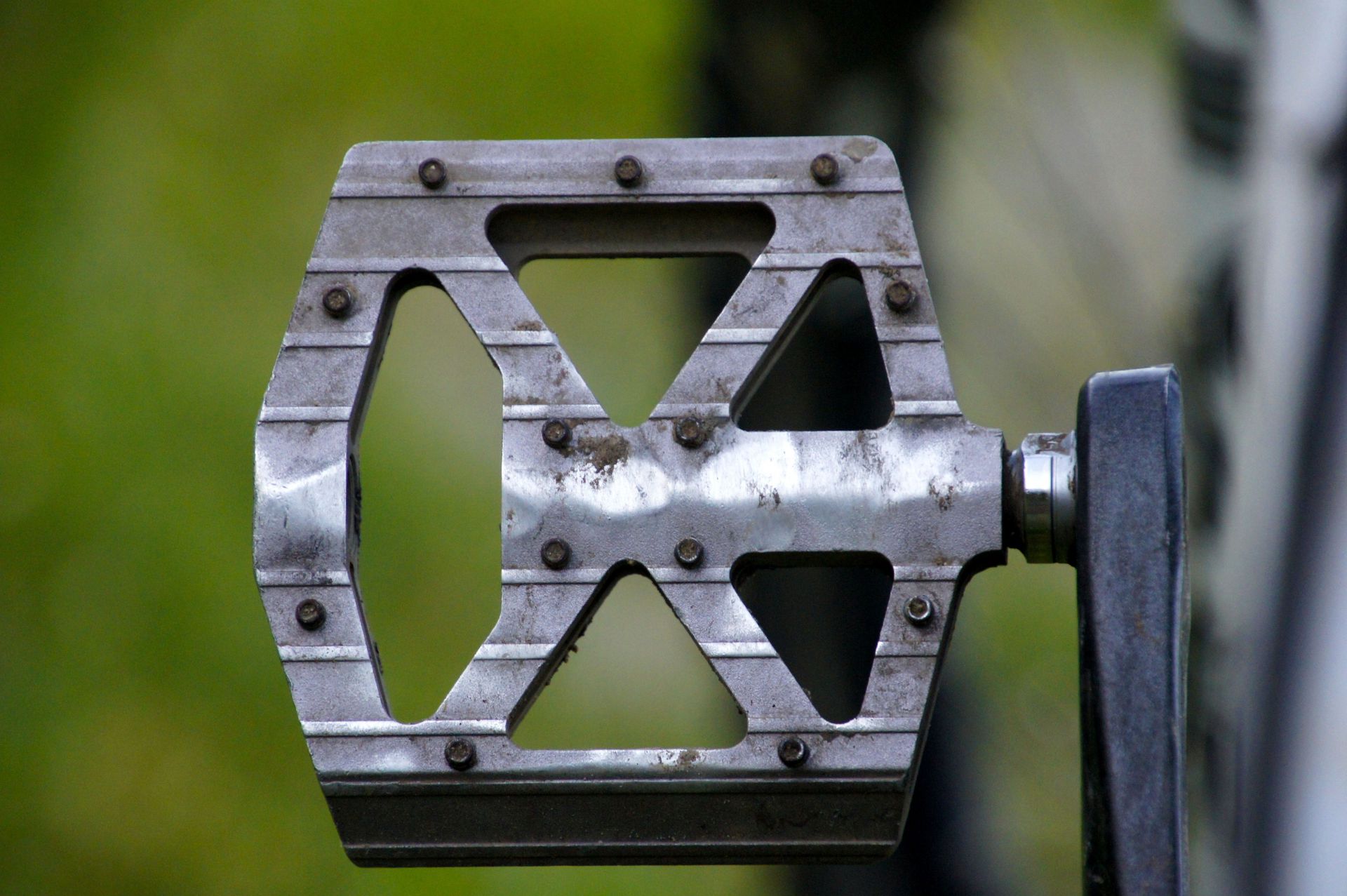

Stamping (bending) blanks are formed without the use of cutting processes. Instead, they are shaped by applying pressure to bend the material into the desired form

Turning blanks are produced through machining, using the relative motion between the blank and a lathe cutting tool to shape the material.

How are these blanks classified?

In terms of appearance, the blanks can be identified as follows:

Turned blanks: have turning tool marks and sharp-edged surfaces.

Stamped and bent blanks: bent blanks usually have curved or arched shapes (created by the bending process); stamped blanks are usually in the form of punched parts.

Sand-cast blanks: usually large in size, with rough surfaces and coarse external appearance.

How are blank surfaces treated?

With these types of blanks, machining often leaves burrs, stamping marks, turning or cutting traces, as well as oil and grease residues on the surface.

These blanks can be processed using various surface finishing methods such as smoothing, brushing, hairline finishing, or mirror polishing through techniques such as:

- Vibratory polishing technology: Uses vibratory finishing machines combined with abrasive media and cleaning solutions to process stamped or sand-cast blanks, suitable for small to medium-sized parts.

- Mechanical polishing technology: Uses mechanical polishing machines such as double-belt grinders or dual-head polishing machines, combined with abrasive tools like flap wheels, felt wheels, sisal wheels, or cloth buffing wheels to achieve a bright, polished surface finish. This method is suitable for blanks with multiple edges and corners, ranging from small to medium sizes, such as turned, stamped, or bent blanks.

In the case of large-sized components requiring high surface finish, specialized grinding machines can be used such as double-head surface grinders (commonly used for flat bar or tube-shaped parts), three-station straight tube polishing machines (commonly used for round or tubular parts), and various other high-tech grinding machines such as shot blasting. and sandblasting machines (also known as shot blasting barrels) used for creating surface roughness.

Hopefully, with the knowledge mentioned above, you now have suitable options for surface treatment of workpiece components in mechanical processing.

Watch the video for full details:

With over 10 years of development in the market, LEKAR is proud to be a leading provider of products in the field of metal surface treatment.

We offer 100% free sample testing and solution consulting, as well as customized mechanical surface processing services. Our team is always ready to provide the fastest support in technology transfer for our customers.

Don’t hesitate, get started today | Perfect Surface – Creating Success

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi. Tel: 02437 646469.

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386.

Website: danhbongkimloai.com.vn | lekar.vn