In engineering, many components feature conical surfaces, which can be used for assembly, positioning, structural enhancement, or aesthetic improvement. In the following article, LEKAR introduces the Tube Swaging Machine – an ideal modern processing machine.

Today, the machining of conical surfaces is carried out using CNC-controlled machines, with programs developed by engineers using professional software. As a result, accuracy, quality, and productivity are significantly improved.

1. General introduction

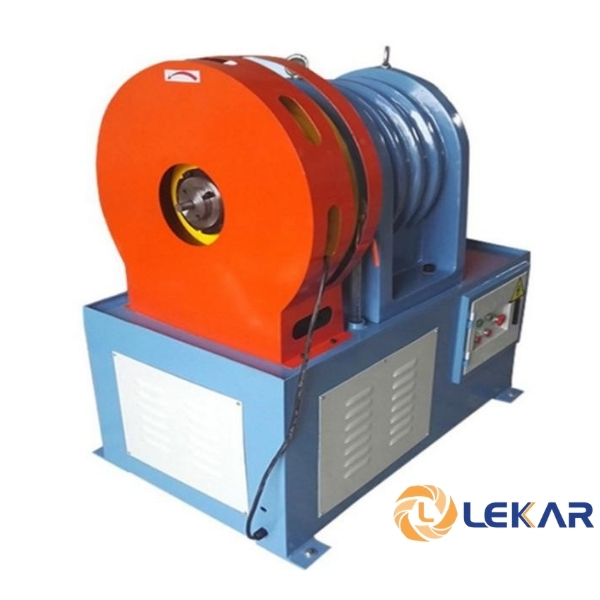

The Tube Swaging Machine is a multifunctional, high-tech product recently researched and developed by applying advanced domestic and international technologies. This machine uses dies to swage and form conical shapes on hollow tubes of various diameters.

This type of machine helps save costs, time, and labor while significantly improving work efficiency.

2. Features

– This machine applies the cold forging method to shape and elongate pipe fittings into cylindrical or conical forms.

– It is equipped with a closed-circuit lubrication system, ensuring stable operation over long periods.

– By combining various compatible dies, the machine can process workpieces of different shapes and sizes. The finished products are consistently smooth, shiny, and highly durable.

Products after machining with a lathe

3. Spec

| TSKT | Unit | JY-25 | JY-40 | JY-60 | JY-75 | JY-114 |

|

|

MM | 200 | 300 | 350 | 400 | 500 |

|

|

MM | 25*2.0 | 40*2.0 | 63*2.0 | 75*2.0 | 114*2.0 |

|

|

MM | 1/2*25 | 1/2*40 | 1/2*60 | 1/2*75 | 1/2*114 |

|

|

Giây | 6~8 | 8~12 | 12~15 | 15~18 | 15~18 |

|

|

KW | 2 | 3 | 5.5 | 11 | 15 |

|

|

HP | 1 | 1 | 2 | 3 | 4 |

| Die | Cái | 4 | 4 | 4 | 4 | 4 |

|

Cooling motor |

W | 90 | 90 | 90 | 400 | 500 |

|

|

DxRxC | 1200*700*1200 | 1500*900*1400 | 3000*1300*1500 | 2200*1700*1700 | Made-to-order |

Precautions for operating and using the Tube Swaging Machine

- Do not enter the machine’s operating area while it is running.

- The machine operator must remain within reach of the emergency stop switch.

- The machine must be operated by personnel with in-depth knowledge of its functions.

- Turn off the power immediately if the machine malfunctions.

- Keep the machine and work environment clean.

- For safety, always turn off the power when installing dies.

- Place the machine on a stable, flat surface and adjust its balance to ensure stable operation.

- Check the motor rotation direction; if incorrect, adjust the power wiring accordingly.

- When using control buttons, press lightly with your fingers; do not use hard objects to push the buttons.

4. Where can you purchase a Tube Swaging Machine that ensures reliability and quality?

If you are still unsure where to purchase a Tube Swaging Machine, LEKAR Group is a highly recommended option. With over 10 years of establishment and development, LEKAR Group is a reputable and highly regarded company in the supporting industry in general, and in the field of metal surface treatment in particular. LEKAR not only supplies grinding machines and polishing machines imported from countries with advanced industrial sectors such as Thailand and China, but also provides modern technological solutions, including CNC-controlled machines.

For more detailed consultation on Tube Swaging Machines as well as other machinery and consumables from LEKAR Group, please contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Xuan Phuong Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc, Hanoi – Tel: 0243 7646469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City – Tel: 02873 033386

Website: danhbongkimloai.com.vn | lekar.vn