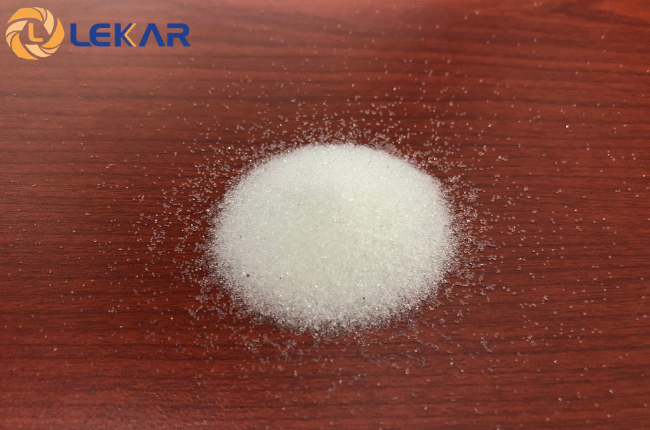

Silica sand is widely used in daily life, with one of its key components serving as a vital base material across various industries.

Characteristics of Silica Sand

Although silica sand has relatively low economic value, its main component – SiO₂ – is an essential material in many industries that directly serve everyday life. In its natural state, silica sand exists as inert crystalline granules. It is commonly extracted through washing and screening processes.

Silica sand contributes to the effective treatment of metal surfaces

Is a material widely used for sandblasting machines and surface treatment of products. It is particularly used in metal surface treatment. Premium silica sand has a spherical shape, which allows it to balance internal pressure and resist breakage. It can withstand multiple impacts, making it suitable for continuous reuse.

In the product surface treatment industry, silica sand helps remove rust and corrosion without damaging the underlying material. It is also used in conjunction with sandblasting machines to clean surfaces without altering the product’s quality or aesthetics, and it does not cause environmental pollution.

Advantages: Chemically inert, free from heavy metals that harm the environment; it provides fast cleaning and can be reused multiple times, offering high economic efficiency; and it enhances aesthetics with a uniform, matte finish.

Silica Sand Resources in Vietnam

Vietnam has large silica sand deposits, most of which are found in open-pit mines, making them easy to extract. The highest concentration of silica sand is in the central region of the country. Specifically, the province of Khanh Hoa is home to four silica sand mines with a total reserve of about 64 million tons. The silica sand from Khanh Hoa is globally renowned for its quality, low impurities, and suitability for producing high-grade glass. As a result, silica sand from this region is frequently exported to Japan, followed by South Korea, China, the Philippines, Malaysia, and other countries. However, in the early stages, Khanh Hoa and many other central provinces mainly exported raw materials, so the profits gained were not significant.

Although Vietnam possesses large silica sand resources, the silica sand processing industry is still at a low level and underdeveloped, which leads to the export of mostly raw materials at a low value.

The Silica Sand Industry in Vietnam has strong potential for development

Given the factors mentioned above, Vietnam is considered one of the emerging economies with high growth potentia this age of industrialization and modernization. Raw materials such as silica sand and industrial infrastructure are being prioritized and are expected to experience significant growth in the near future.

The global demand for silica sand is forecast to increase by 5.6% annually, while the demand for building materials made from sand, such as Cemboard panels, float glass, and tempered glass, is experiencing tremendous growth in the market. Currently, Vietnamese companies are primarily focused on supplying raw materials, indicating that the silica sand market still holds substantial untapped potential.

For all inquiries and purchases, please contact:

LEKA METAL POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi. Tel: +84 243 7646469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: +84 2873 033386

Website:danhbongkimloai.com.vn | lekar.vn