Overview on Tube Polishing Machine

The Tube Polishing Machine is a specialized machine for polishing surfaces of tube-shaped metal workpieces. The machine is highly flexible as it is compatible with all kinds of polishing wheels such as flap wheels, nonwoven wheels, buff wheels, etc. The machine can be used to deburr, smooth and polish surfaces of tubes made from metals such as stainless steel, copper, cast iron and aluminum.

Tube Polishing Machine with installed flash light

Components and Principles of Operation

The Tube Polishing Machine consists of 8 main components: machine body, motor, working station, roller, spindle, clamp, protector and controller.

Principles of Operation:

- The tube-shaped workpiece is put into the V-shaped clamp and then fed to the grinding wheels by the drive from the motor. The speed is adjustable upon installation of an inverter.

- The Tube Polishing Machine operates on the principle of centreless grinding. Therefore, the workpiece just needs to be fed into the V-shaped clamp to work under the drive from the motor, instead of being precisely positioned as in some other machines.

Typical uses of Tube Polishing Machine

- Remove defects on metal surfaces.

- Smooth, polish or create hairline finish for surfaces.

- Create desired level of roughness on surfaces.

- Create satin finish for surfaces.

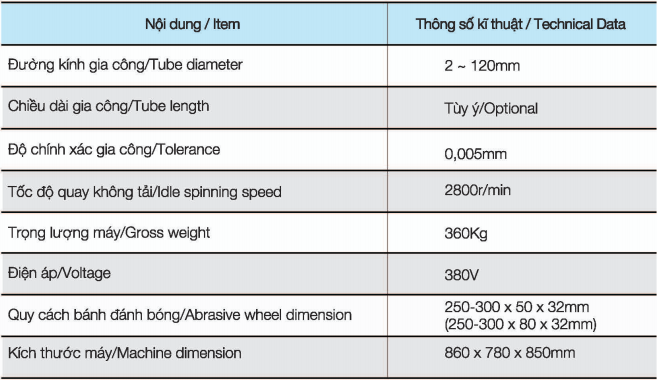

SPEC:

Stainless steel tube polishing process by Tube Polishing Machine:

For more information on Tube Polishing Machine and other products, services from LEKAR, please contact:

LEKA Polishing Technology Joint Stock Company – LEKAR GROUP

Northern Office: CN2 Lot, Tu Liem Industrial Zone, Minh Khai Ward, Bac Tu Liem District, Hanoi.

Tel: 0243 7646469

Southern Office: D7 Road, KCN Nam Tan Uyen, Khanh Binh Ward, Tan Uyen Town, Binh Duong.

Tel: 02873 033386

Email: info@lekar.vn