Overview on Automatic swing two-station (wet & dry) polishing machine, conveyor included

Two-station (wet & dry) polishing machine is a specialized machine for processing the surfaces of metal rectangular tubes and sheets. Distinctive features of the machines lie in the conveyor and 2-station (wet & dry) grinding system, which helps to save time, labor costs and protect the environment.

This machine is mostly used in smoothing, creating hairline finish and polishing metal workpieces that are in flat and rectangular bar shapes.

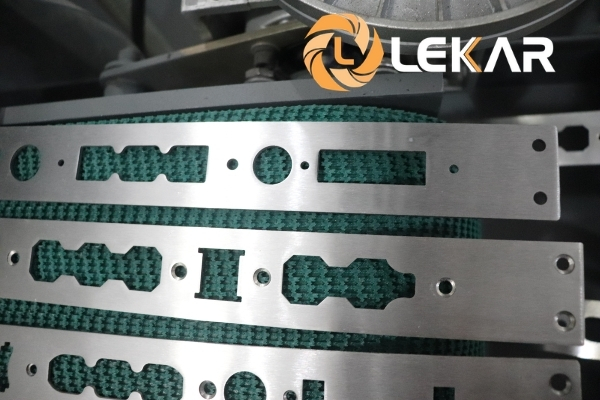

Flat bars after being processed by Two-station (wet & dry) polishing machine

SPECS

Dimension (LxWxH): 2000x1500x2000mm

Workstation height: 0~100mm

Motor: 4kw*2

Spindle speed: 2160 rpm

Linear velocity: 17.58m/s

Conveyor motor: 2.2kw

Water pump: 450w

Belt dimension: 2100x150mm

Nonwoven wheel: 250x150mm

Workstation width: 150mm

Voltage: 380v 50HZ

Total motor: 11kw

Two-station (wet & dry) polishing machine has many advantages over other types of grinding machines

Advantages of Automatic swing two-station (wet & dry) polishing machine, conveyor included

– Two-station (wet & dry) polishing machine is a newly introduced machine from countries with developed industries.

– Two-station (wet & dry) polishing machine can work with all types of metals (iron, copper, aluminum, stainless steel, etc) in various shapes (flat sheets, rectangular bars, tubes) of various uses (household goods, cabins, shelves, sports equipment, frames, etc)

– The machine can be easily operated with an innovative established program, and therefore doesn’t require highly-skilled operation workers. Maintenance is quick and simple.

– The machine helps to substantially reduce labor efforts and costs without compromising product quality and quantity.

– Water is involved in the grinding process, which cools and cleans the workpieces. The wet grinding process allows minimal dusts and increased safety for workers and the environment.

For more information on Two-station (wet & dry) polishing machine and other products, services from LEKAR, please contact:

LEKA Polishing Technology Joint Stock Company – LEKAR GROUP

Northern Office: CN2 Lot, Tu Liem Industrial Zone, Minh Khai Ward, Bac Tu Liem District, Hanoi.

Tel: 0243 7646469

Southern Office: D7 Road, KCN Nam Tan Uyen, Khanh Binh Ward, Tan Uyen Town, Binh Duong.

Tel: 02873 033386

Email: info@lekar.vn