Vibratory separator is a production device that allows for monitoring and protection of the production line by cleaning raw materials and removing complex substances. It ensures the smooth operation of the production process and helps prevent damage to mechanical components. Structure and working principle of the vibratory separator

:

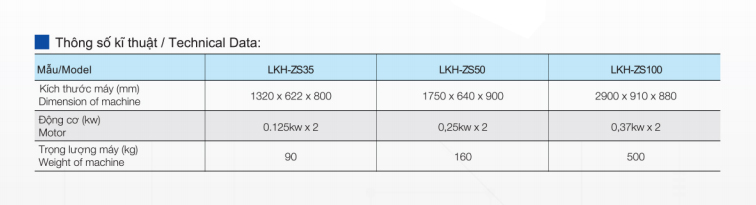

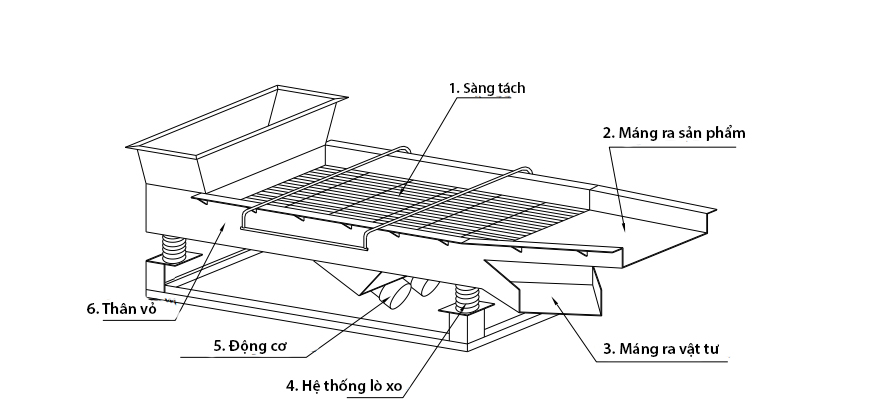

Bản vẽ máy sàng rung

- Screening tray

- Discharge chute for product if product size is larger than screen holes (or discharge chute for media if media size is larger than screen holes)

- Discharge chute for media if media size is smaller than screen holes (or discharge chute for product if product size is smaller than screen holes)

- Spring system

- Motor

- Machine body

1. Operating principle of Vibratory separator

The operating principle of vibratory separators to classify materials by particle size using a perforated metal surface or mesh screen. As the material moves across the screen surface, it is separated into two types:

- Undersized materials, with particle sizes smaller than the screen openings, pass through the screen.

-

The fraction that does not pass through the screen has a particle size larger than the screen openings and therefore remains on the screen surface. Depending on the classification requirements of the bulk material, multi-deck screening systems can be arranged. For example, a two-deck screen separates the material into three different size fractions, while a three-deck screen separates it into four size ranges. The aperture size of the upper deck is larger than that of the lower decks.

The vibrating motion of the screen enhances the classification–cleaning process by increasing the chance for particles to contact the apertures. In continuous operation, the screen is inclined at an angle of 2–7°, causing the particles to move downward. During this downward motion, smaller particles are able to pass through the apertures, while the oversize fraction is discharged at the lower end of the screen.

Depending on the drive system arrangement, the motion of the screen and consequently the particle movement on the screen surface may vary. Typically, screens are designed so that the particles undergo both downward and upward motion, with the downward stroke being longer than the upward stroke.

Factors influencing the screening capacity include:

- Screen surface area is the most important parameter. The larger the surface area, the higher the throughput. The total open area (the area of the screen openings) also directly affects the screening capacity.

- Screening speed: The higher the speed, the greater the throughput.

- Material passing through the screen openings: The higher the amount of material smaller than the screen openings, the lower the throughput of the separator, as more time is required to separate these particles. For an existing screen, the surface area and vibration speed are usually fixed and cannot be adjusted. Therefore, to adjust the working capacity of the separator, the feed rate is modified.

The screening process is achieved through the relative motion of particles on the screen. The greater the relative distance traveled by the particles during the separation process, the higher the probability that will pass through the screen openings.

2. Where to buy high-quality vibratory separator machines with reliability and quality?

To purchase high-quality vibrating separator machines for the production and processing of metal products, manufacturers should seek out reputable suppliers. LEKAR GROUP is one of the best choices for reliable and high-quality equipment.

With years of experience in the metal polishing industry, LEKAR GROUP offers effective solutions that save time and costs for customers. The equipment, including vibratory separator machines, centrifugal drying machines, and grinding machines distributed by LEKAR, are all imported from developed countries in the region such as Thailand and China, ensuring superior quality. Customers can be completely confident in using these products.

In addition to machinery, LEKAR GROUP also supplies consumables for polishing and offers metal polishing services based on customer requests. Customers can opt for this service if they do not wish to purchase machines or consumables for self-polishing their products. For customers who buy machines, LEKAR’s technicians will provide technology transfer and guidance on how to use the equipment.

Those interested in purchasing industrial separator machines or equipment and consumables at LEKAR GROUP, please contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: Unit No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi

Tel: +84 2437 646 469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City

Tel: +84 2873 033 386

Website: danhbongkimloai.com.vn | lekar.vn

Tham khảo sản phẩm: Máy Sàng Tách LKH-ZS