Fine sandpaper for metal polishing, also known as fine abrasive paper, is a type of sandpaper used across various industries such as woodworking, metalworking, stainless steel processing, and painting. As a versatile abrasive material, fine sandpaper is widely applied in both industrial production and daily life.

So, what exactly is fine sandpaper? What role does it play in metal polishing? Let’s explore the answers with LEKAR Group in the article below.

1. What is the grit size of fine sandpaper?

Fine sandpaper refers to sandpaper with a grit size of 1000 or higher, commonly labeled with the letter “P”, such as P1000, P1200, P1500, P2000, or P2500.

With its soft, flexible, and durable characteristics, fine sandpaper can completely remove micro-scratches, create a high-gloss surface finish, and meet strict industry standards. It can be used for wet sanding, dry sanding, or a combination of both, depending on the application requirements.

Fine Sandpaper distributed by LEKAR

2. Structure of fine sandpaper for metal polishing

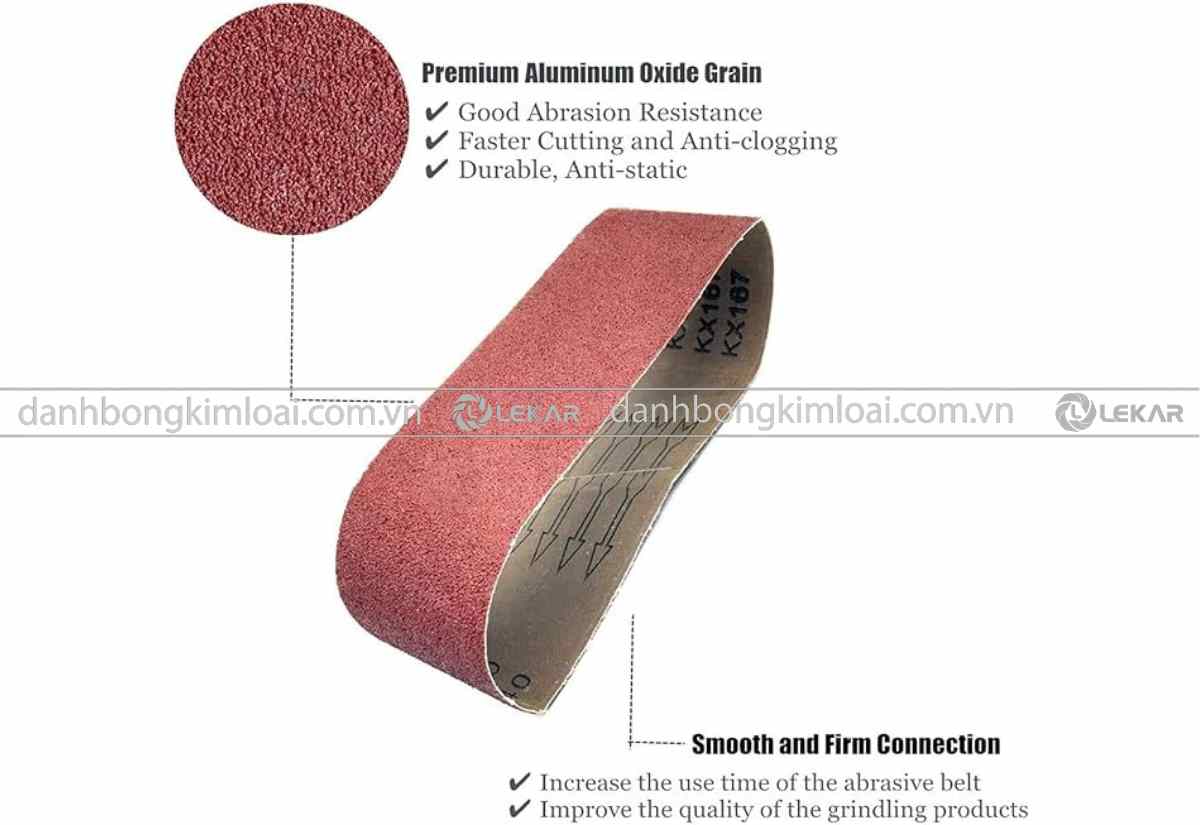

The structure of fine sandpaper for polishing consists of three main components: abrasive grains, adhesive, and the backing layer made of paper or cloth.

-

Abrasive grains are the primary component responsible for the sandpaper’s grinding and polishing ability. Common abrasive materials include flint, garnet, emery, aluminum oxide, silicon carbide, and zirconia.

-

Adhesive serves as the bonding agent that attaches the abrasive grains to the paper or cloth backing.

-

The backing layer, made of paper or fabric, is the base that holds the abrasive grains in place and provides flexibility and durability during use.

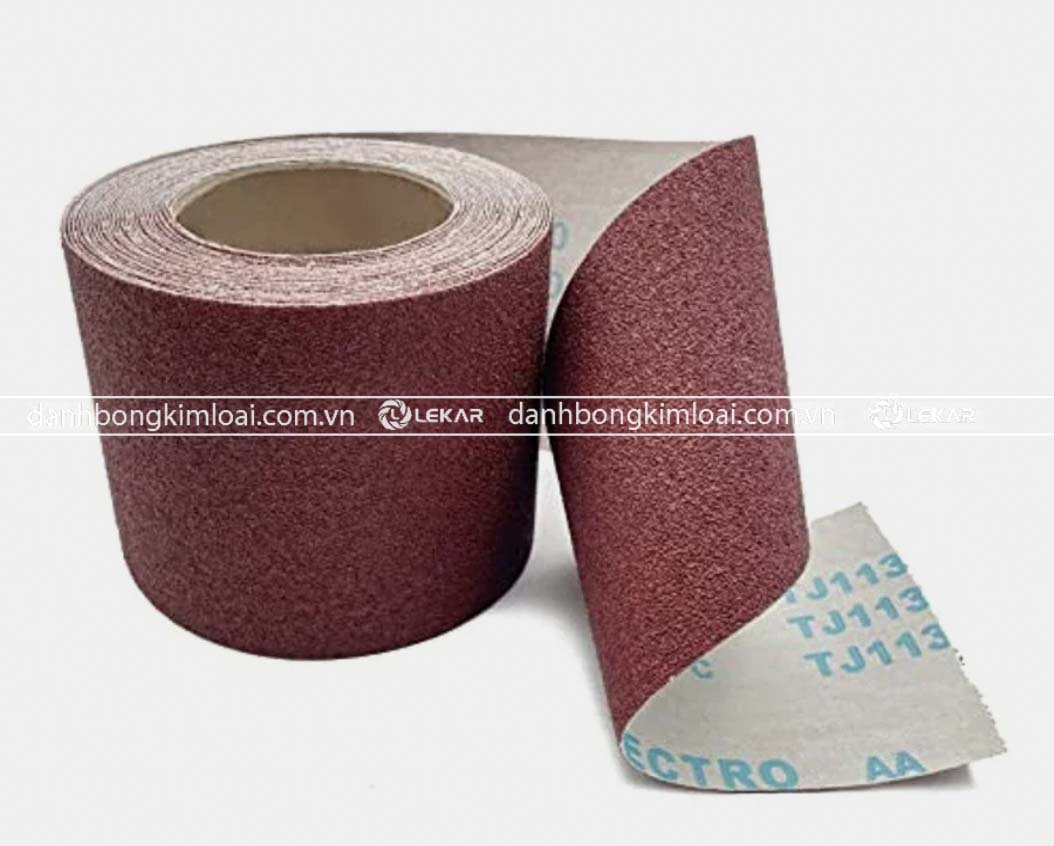

Fine sandpaper for metal polishing in roll form

High-quality fine sandpaper features uniform abrasive grains, with securely bonded joints between sections using high-grade adhesive. The backing layer is made from premium materials, giving the sandpaper superior durability compared to low-quality or unbranded products available on the market.

3. Main functions of fine sandpaper

Ordinary sandpaper products may leave visible scratches on the surface during sanding, which can reduce the aesthetic appeal and quality of the finished product. Fine and ultra-fine sandpaper effectively eliminates this drawback, creating a smoother, more refined, and visually appealing surface compared to conventional types.

*Fine and ultra-fine sandpaper can be used for wet sanding, dry sanding, or a combination of both. However, for the best results and highest gloss, wet sanding is recommended. When used in wet conditions, certain types of fine polishing sandpaper can be dried and reused, making them both efficient and economical.

Some notes when using fine sandpaper for metal polishing

– To achieve the best polishing results, in addition to choosing the right type of sandpaper, users must also apply the correct usage techniques.

– When sanding by hand, it is recommended to wear gloves, a mask, and safety goggles to prevent dust or metal particles from entering the eyes, nose, or causing scratches and skin irritation.

– When using sandpaper with polishing or grinding machines, ensure that all connections are properly secured to avoid components coming loose during operation, which could lead to workplace accidents.

Image of a belt grinding machine using fine sandpaper for metal polishing

Check out this video about metal polishing sandpaper distributed by LEKAR:

Where to buy High-Quality fine sandpaper for metal polishing

With over 10 years of experience in the metal surface treatment industry, LEKAR is proud to be a leading provider of comprehensive solutions, materials, and machinery for metal surface finishing. In particular, we specialize in supplying high-quality fine sandpaper for metal polishing, trusted by customers across various industries.

All of our products are carefully selected by a team of skilled technicians with years of experience, ensuring both excellent quality and reasonable pricing in the market.

Contact us today for timely consultation and support!

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc, Hanoi | Tel: 02437 646 469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City | Tel: 02873 033 386

Website: danhbongkimloai.com.vn | lekar.vn