4 common types of blasting sand today are widely applied in surface treatment industries such as cleaning, roughening, coating, and metal polishing. Each type of abrasive has distinct characteristics, hardness levels, and efficiency, making it suitable for specific materials and purposes. Choosing the right abrasive not only helps optimize costs but also ensures the quality of the treated surface. The following article will help you clearly distinguish the four commonly used blasting abrasives along with their advantages and disadvantages.

1. Usages of Blasting Sand

+ Removing old paint layers

+ Smoothing surfaces and creating a polished finish

+ Removing rust from old components

+ Cleaning molds

+ Preparing surfaces before plating, coating, or painting

+ Creating decorative or custom patterns on glass surfaces

2. How Blasting Sand Works in Sandblasting and Shot Blasting Systems

Under the force of compressed air (dry blasting) or water pressure (wet blasting), abrasive sand is propelled and impacts the target surface with high force. This impact causes abrasion and intentional surface deformation or removal to achieve the desired cleaning effect

Shot Blasting / Sandblasting Technology

3. Common Types of Blasting Sand Used in Metal Polishing Today

Aluminum Oxide

Aluminum oxide (Al₂O₃), also known as alumina, is an excellent thermal and electrical insulator. In its crystalline form, it is called corundum (CAS No. 1302-74-5). With a high Mohs hardness of up to 9 and a melting point of 2050°C, it is well-suited for use as an abrasive material and as a component in cutting tools.

Aluminum oxide grit is widely used in surface cleaning of metal parts, such as rust, stain, and weld removal prior to painting, plating, or coating. It is also applied in grinding carbon alloy products, high-speed steel, hardened steel, and casting molds. Common industries using this media include shipbuilding, automotive, motorbike manufacturing, and general mechanical engineering.

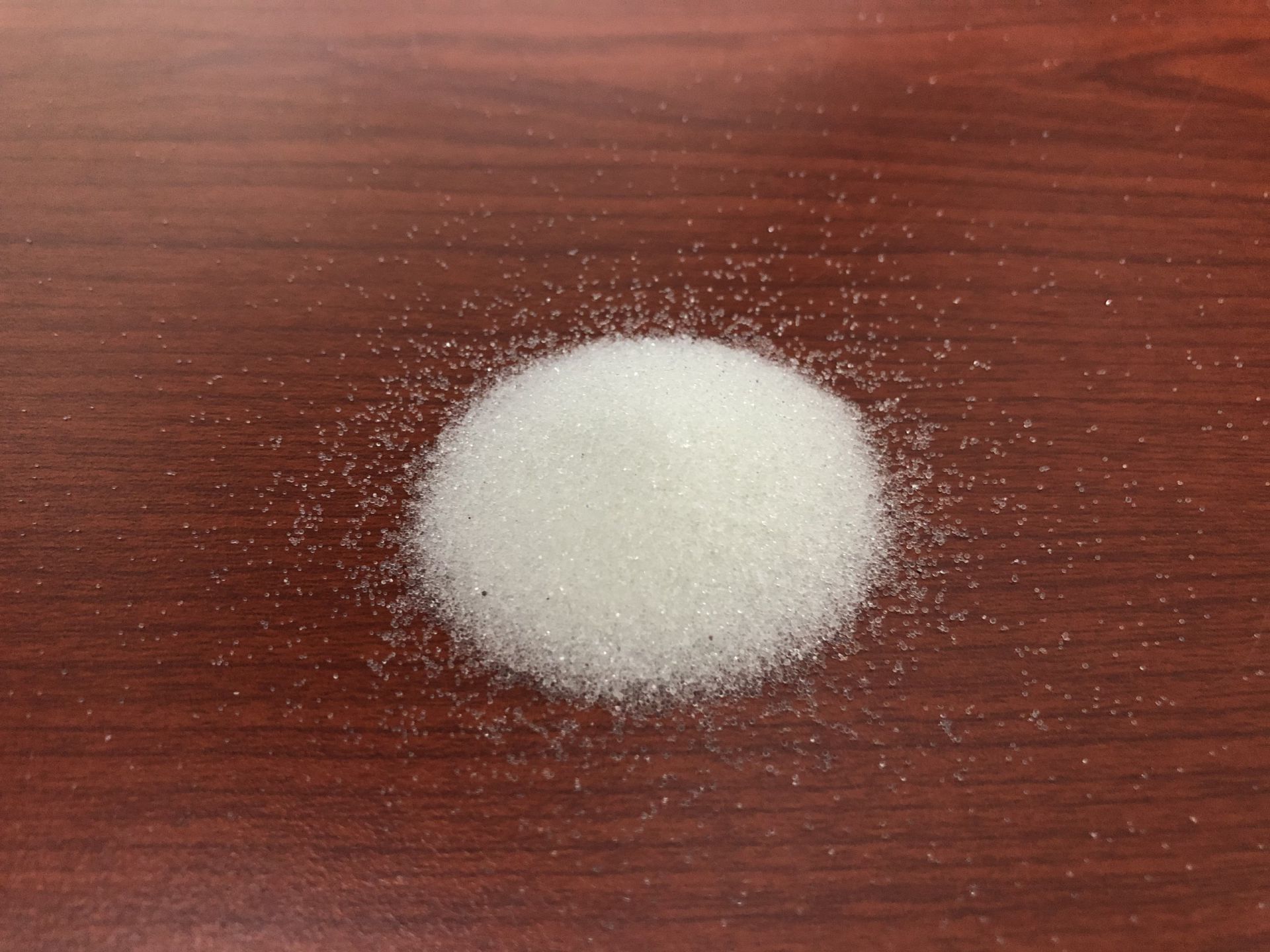

Glass Beads

Glass beads are colorless and transparent abrasive materials with stable chemical properties, high hardness, and heat resistance (Mohs > 5.0). Glass beads come in angular or spherical shapes and do not damage the surface of the workpiece or affect its dimensional accuracy. This helps minimize nozzle wear and extends equipment lifespan.

Glass beads are used in surface treatment of metal components, such as removing rust, paint, carbon deposits, scratches, and blemishes from metal tubes and precision non-ferrous castings. Glass beads are also widely applied in polishing medical equipment, textile machinery, and various hardware products. Additionally, glass beads are used to clean metal and rubber molds, remove rust and contaminants, and add decorative finishes to handicrafts.

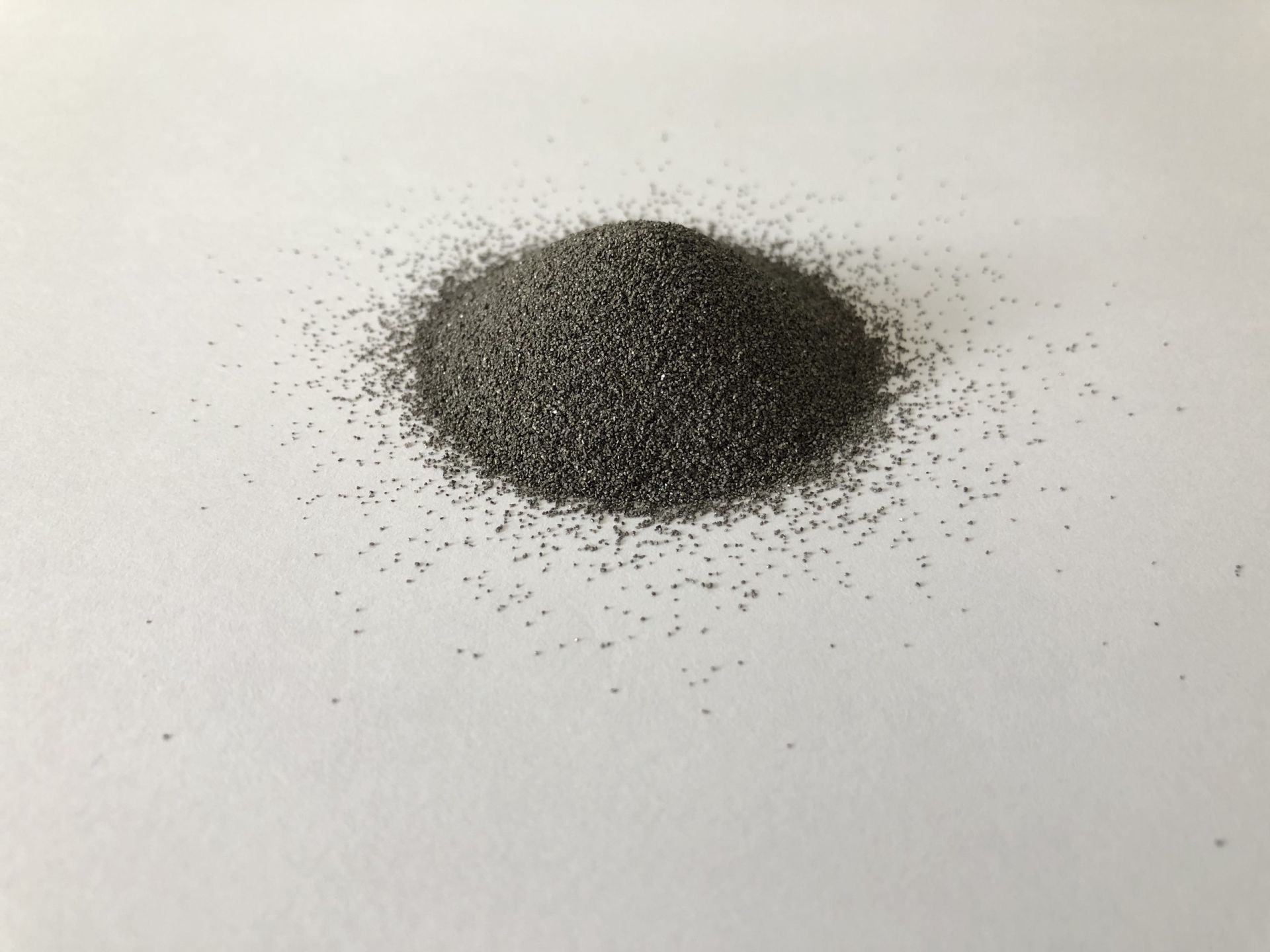

Steel Grit

Steel grit is made from scrap of high-carbon steel or alloy steel.

In terms of shape, the particles are polygonal, angular, and come in various shapes and sizes, with high consistency within the same grit size.

Steel grit used in blasting systems can:

1. Clean steel surfaces before painting; treat surfaces of high-temperature materials such as scale, rust, and welds by directly blasting onto the metal surface.

2. Remove sand from castings and shape edges; clean parts with burrs, moulds, and forged components.

3. Clean steel structures and create uniform surfaces before painting, plating, or enamelling.

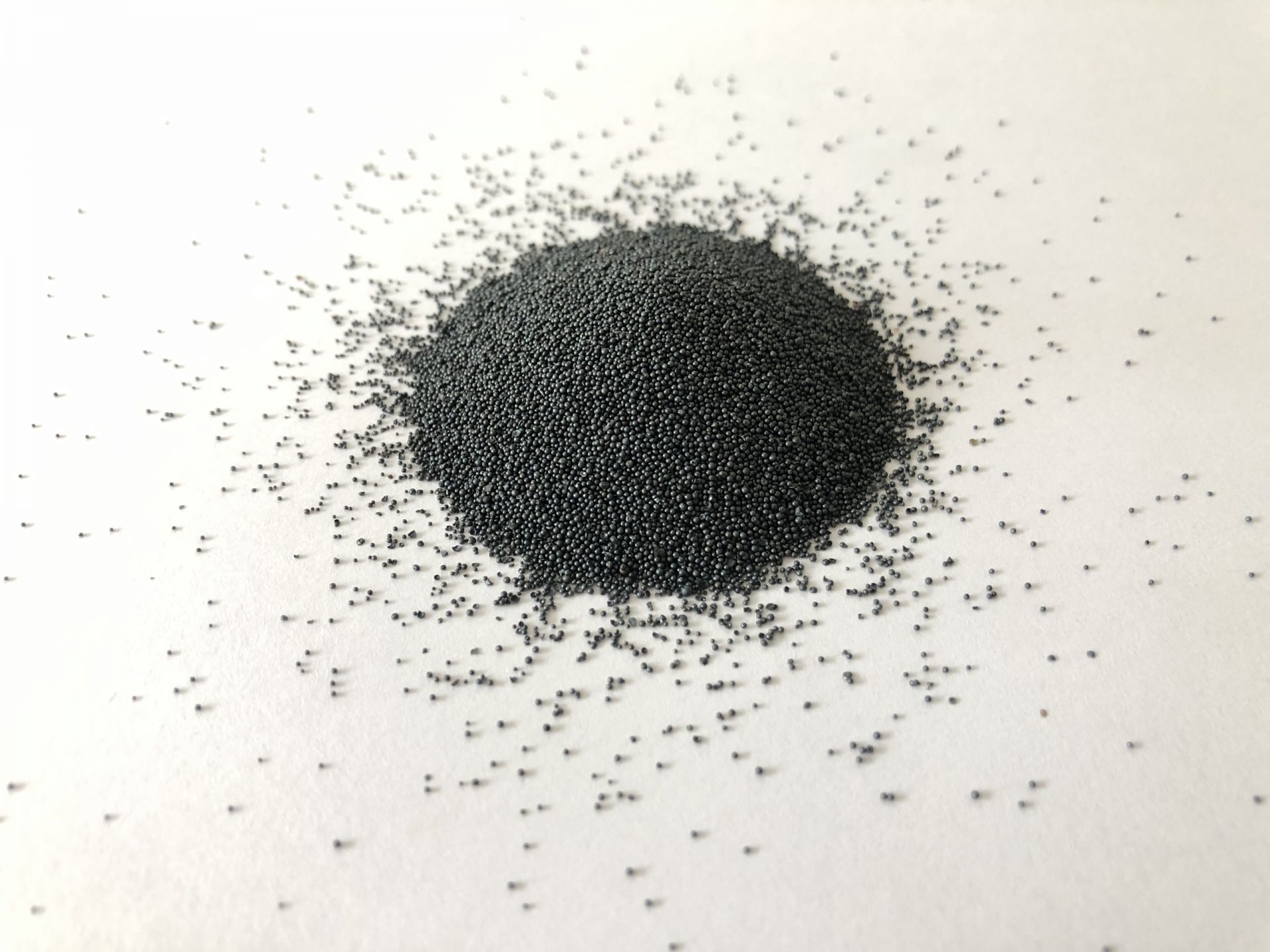

Steel Shot

Steel shot is made from scrap of high-carbon steel or alloy steel.

In terms of shape, the particles are solid and spherical.

The shot is round and uniform, with high rebound and hardness.

It provides stable surface strengthening and cleans the surface without affecting the workpiece – no change in the original size or shape.

For detailed consultation on blasting abrasives, consumable materials, polishing machines, and other services provided by LEKAR, please contact:

LEKA Polishing Technology Joint Stock Company – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Xuan Phuong Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi.

Tel: 0243 7646469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City.

Tel: 02873 033386

Website: danhbongkimloai.com.vn | lekar.vn