Uses of Automatic swing flat polishing machine, 1 nonwoven wheel station, hairline finishing

The Automatic flat hairline polishing machine is a hi-tech grinding machine, specifically designed for processing flat surfaces of metals such as iron, aluminum, stainless steel,……

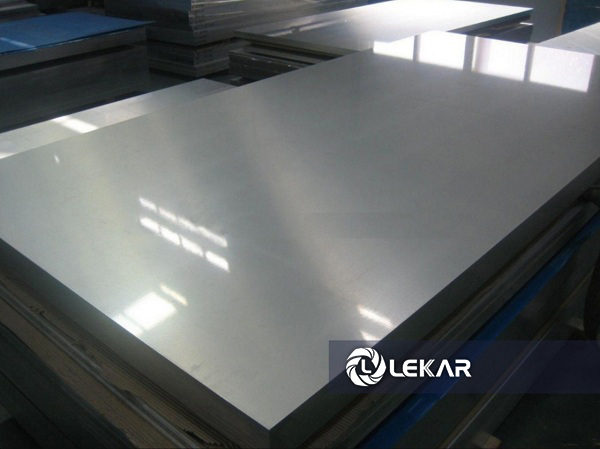

Large sheets of metals are normally cut into smaller sheets by the cutting machines in order to make them more conveniently processed. The cutting process may leave undesirable lumps, cuts, and burrs on the metal surfaces.

Automatic flat hairline polishing machine creates a perfect finish for sheet metal surfaces

Unprocessed metal surfaces now need to undergo polishing to remove these defects. This can be conducted by the Automatic flat hairline polishing machine. When used with nonwoven wheels, this machine effectively grinds, deburrs, polishes metal surfaces; especially this machine also creates hairline and satin finish on metal surfaces.

Hairline and satin finish bring about chic, elegant surfaces. Manufacturers of stainless steel sheets used in elevators often choose hairline finish to improve the product appearance and increase customer satisfaction.

SPECS

- Conveyor belt motor: 1.1 KW

- Main motor: 7.5 KW*1

- Dimension: LxWxH = 1800x1700x2000mm

- Voltage: 380V 50HZ

- Total motor: 8,42KW

- Wheel dimension: Ø250mm; maximum width 610mm.

- Conveyor belt speed can be adjusted with inverter

- Weight: 1500kg

Highlights of Automatic swing flat polishing machine, 1 nonwoven wheel station, hairline finishing

The Automatic flat hairline polishing machine can work on a variety of metals including iron, aluminum, copper, stainless steel, etc. This machine offers high levels of surface evenness and better efficiency compared to the traditional grinding machine.

Automatic flat hairline polishing machine can work on a variety of metals including iron, aluminum, copper, stainless steel, etc

The Automatic flat hairline polishing machine helps cut down on labor costs. Instead of hiring workers to operate on multiple traditional grinding machines, using the Automatic hairline finishing machine (using nonwoven wheel) helps manufacturers achieve high effectiveness with minimal need for workers.

The machine can be easily operated by workers. Workstation height is adjustable, and grinding speed can be adjusted with the inverter.

The machine is equipped with a water grinding system that cools and lubricates workpieces, which ensures minimal amount of dust that can be harmful to the working environment. Customers can opt for dry or wet processes.

Due to these features, the Automatic flat hairline polishing machine is an essential machine for sheet metal manufacturers. This machine plays an important role in determination of the product value, and therefore manufacturers need to carefully research in order to select a high-quality machine.

The Automatic flat hairline polishing machine offers high efficiency and minimal lead time

LEKAR Group – Trusted provider for Automatic swing flat polishing machine, 1 nonwoven wheel station, hairline finishing

With 10 years of expertise in the polishing industry, LEKAR Group is proud to be the leading provider of polishing machines and materials at the best prices in the market. Products from LEKAR Group are the top choices for manufacturers in Vietnam.

LEKAR Group is the importer of vibratory polishing machines, belt grinding machines, sand/steel blasting machine, Automatic hairline finishing machine (using nonwoven wheel)… from developed markets such as Thailand and China. Polishing machines by Thai and Chinese manufacturers have proven quality, stability and efficiency.

LEKAR Group also provides consumable polishing materials such as nonwoven wheels, buffing wheels, sisal wheels, polishing compounds, abrasive coated belts, etc. Polishing materials are of high quality and suitable for different types of polishing machines.

LEKAR Group offers product warranty and outsourcing service as per customer request in order to meet various demands from customers. LEKAR Group is a trusted and highly supportive partner to manufacturers.

For more information on Automatic swing flat polishing machine, 1 nonwoven wheel station, hairline finishing and other products and services from LEKAR Group, please contact:

LEKA Polishing Technology Joint Stock Company – LEKAR GROUP

Northern Office: CN2 Lot, Tu Liem Industrial Zone, Minh Khai Ward, Bac Tu Liem District, Hanoi.

Tel: 0243 7646469

Southern Office: D7 Road, KCN Nam Tan Uyen, Khanh Binh Ward, Tan Uyen Town, Binh Duong.

Tel: 02873 033386

Email: info@lekar.vn