With over 10 years of experience in the industry, LEKAR LEKAR currently provides SA 2.5 standard sandblasting services for metal surface cleaning at the best prices for all customers.

Sandblasting is a familiar method used in the industrial and surface treatment sectors. It typically employs abrasive media such as steel balls, glass beads, or aluminum shot, which are blasted onto the surface of a product at high speed. Through friction and impact, the surface is thoroughly cleaned, creating favorable conditions for subsequent processing steps.

>>>Xem thêm: Máy bắn cát công nghiệp

Sandblasting is applied in many different industries with outstanding benefits such as:

In the manufacturing industry: sandblasting cleans and removes rust and dust and creates a clean surface for steel structures, steel beams, aluminum formwork, and metal sheets.

In the automotive industry: sandblasting helps clean surfaces, making repainting or repair processes faster and more efficient.

In the maintenance and refurbishment of household products: it helps increase durability and aesthetics.

In powder coating processes: it ensures good adhesion and the final quality of the product.

Product before and after sandblasting

Why should you choose LEKAR’s sandblasting cleaning service?

Instead of investing a large amount of capital in purchasing machinery and materials, many customers have turned to LEKAR’s sandblasting cleaning service. Several key advantages make LEKAR the trusted choice:

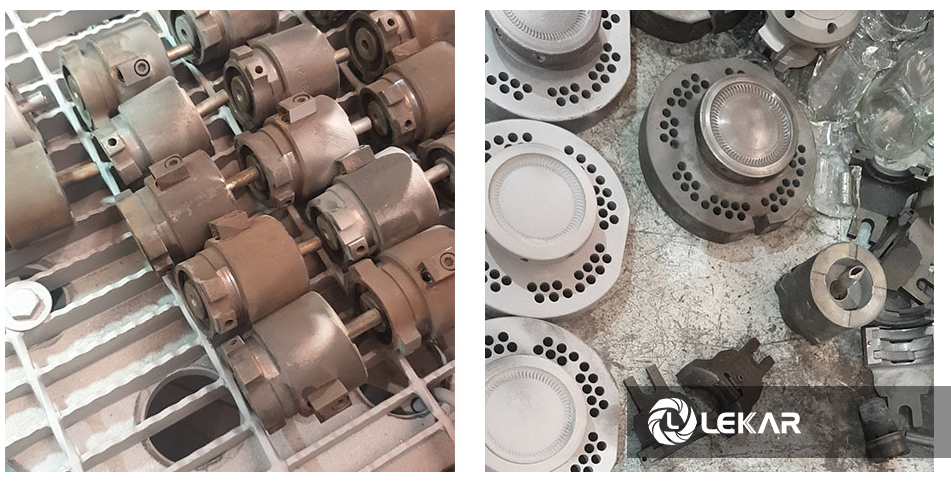

A supplier and designer of sandblasting machines in various models

LEKAR is not only a provider of sandblasting services but also offers a wide range of sandblasting machines with diverse designs and functions. This means you have multiple options to best meet your metal surface treatment requirements. Some of the sandblasting machines currently in use at LEKAR include transmitting shot blasting machines, manual environmental protection type sandblasting machines, drum automatic sand blasting machine,…

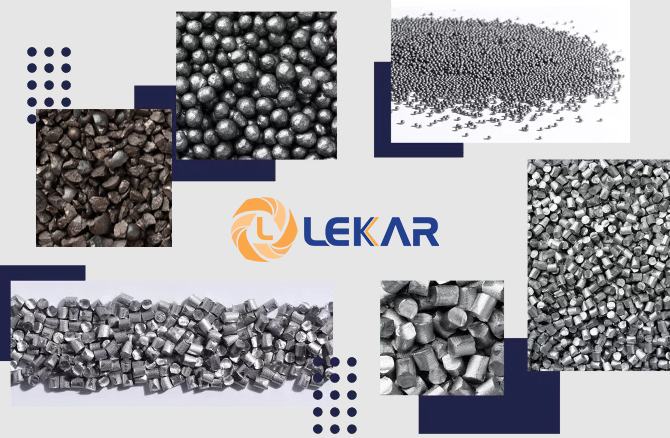

Ensuring a stable supply of materials to meet production demands

A critical factor in the sandblasting process is the consistent and proactive supply of materials. At LEKAR, we are committed to maintaining a stable inventory of high-quality abrasives to fully meet the surface treatment needs of our clients. We ensure sufficient quantity and a wide selection of abrasive materials to support various project requirements.

Committed to meeting all customer needs for product surface treatment

Blasting technology tailored to customer needs

Surface Finish Meets SA 2.5 Standard: LEKAR guarantees that all surfaces after sandblasting meet the international cleanliness standard SA 2.5. We consistently strive to minimize errors throughout the surface treatment process to ensure the highest surface quality for the final product. This creates optimal conditions for subsequent processing stages.

Most competitive pricing on the market

Thanks to advanced technology and high-quality materials, LEKAR helps reduce operational costs throughout the entire process. As a result, we offer sandblasting services at the most competitive prices for our customers.

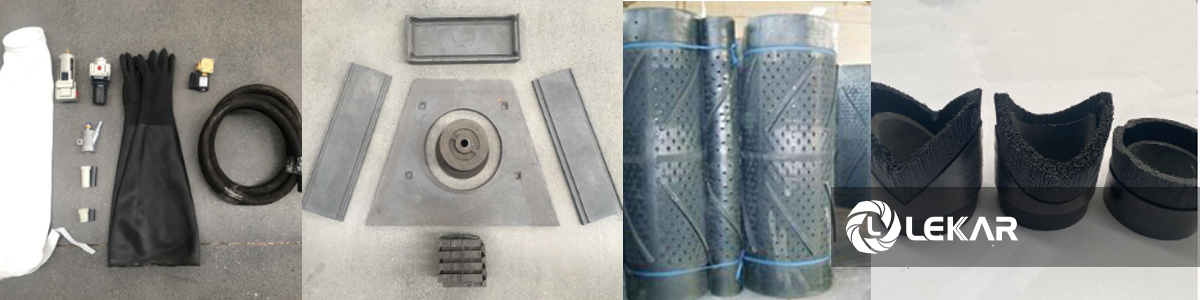

Genuine peplacement materials

As a leading partner of top polishing material manufacturers and brands, LEKAR is committed to providing genuine replacement materials. This ensures not only the quality and effectiveness of the sandblasting process but also improves product durability and helps save both time and cost.

Genuine replacement parts.

Consultation on optimal technical solutions

With over 10 years of experience in the field, LEKAR’s team of engineers and specialists is always ready to listen and provide optimal technical solutions for every customer.

LEKAR’s SA 2.5 surface standard after sandblasting

When performing surface treatment using sandblasting machines, manufacturers apply SA standards to assess the effectiveness of the process. Among these, the SA 2.5 surface standard is the most commonly used and is regarded as a benchmark for product quality after sandblasting.

According to the SA standard, a surface that has undergone sandblasting to SA 2.5 level achieves high technical quality, with a color similar to the original metal. Rust marks may appear only as very slight streaks or fine threads. After blasting, the surface is cleaned using dry compressed air or a clean brush.

To achieve the SA 2.5 surface standard, LEKAR places strong emphasis on the use of sandblasting machines, materials, and professional technical expertise. This is demonstrated through the following factors:

Polishing efficiency

LEKAR uses abrasive grains ranging from 0.3 mm to 1.5 mm in size. This ensures a uniform polishing effect across the metal surface.

In addition, for deep holes or recessed surface areas, using smaller-sized abrasive grains helps access and clean hard-to-reach areas effectively.

Drum automatic sand blasting machine – An Optimal Time-Saving Solution for Businesses

Removal of impurities

Smaller-sized abrasive grains are effective in removing contaminants such as rust, oil, grease, and other impurities from metal surfaces.

Surface oughness

The size of the abrasive grains can affect the surface roughness. Smaller abrasive grains can create a smoother surface, while larger grains can result in a rougher surface.

Note: The selection of the appropriate abrasive grain size depends on various factors, such as the type of metal, the desired surface finish, and specific requirements of the surface preparation process.

If you are interested in high-quality, cost-effective sandblasting services for cleaning metal surfaces, please contact LEKAR for assistance at the following address:

LEKA METAL POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Xuan Phuong Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc Commune, Hanoi. Tel: 0243 7646469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386