To achieve smooth, clean, and aesthetically pleasing aluminum surfaces that meet the requirements for subsequent industrial or consumer product manufacturing processes, technicians often apply sandblasting technology. So how is sandblasting performed to clean aluminum surfaces, and what are the advantages of this method? Let’s explore the details in the following article.

Products after being treated with a sandblasting cleaning machine.

Why should you use sandblasting to clean aluminum surfaces?

In the past, to clean aluminum and other metal surfaces, workers mainly relied on manual scrubbing. However, this traditional method revealed several limitations such as being time consuming, labor intensive, posing health risks due to dust inhalation, delivering low cleaning efficiency, and incurring high costs.

As technology advanced, chemical cleaning methods were introduced. Yet, despite improving speed, chemical cleaning presented environmental and safety hazards, along with significant handling and disposal costs. Moreover, surfaces cleaned with chemicals often lacked the necessary roughness for proper paint adhesion. Chemical cleaning is still occasionally used today for thin aluminum surfaces that cannot withstand mechanical cleaning.

Overcoming these drawbacks, sandblasting technology emerged as a superior cleaning method and has become increasingly popular. This process uses an industrial sandblasting machine to propel abrasive media at high speed onto the aluminum surface. The sharp, angular particles effectively remove rust and old coatings while creating the ideal surface roughness for subsequent coating or painting. The degree of roughness can be adjusted by selecting abrasives of different grit sizes.

With sandblasting, aluminum surfaces are thoroughly cleaned without deformation, retaining the required brightness and finish quality for further processing. In addition, the method helps protect workers’ health, reduce working time, and streamline production, resulting in significant cost savings for manufacturers and contractors.

Among aluminum surface cleaning sandblasting machines, there are two main types currently in use:

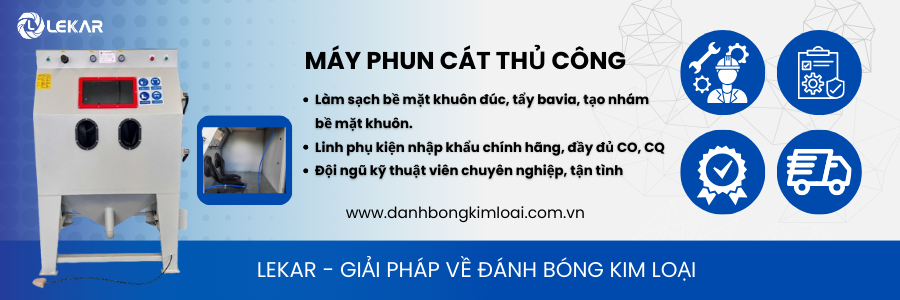

Manual Environmental Protection Type Sandblasting Machine LKPC-TC52-0.55: this machine uses compressed air energy to blast abrasive sand particles at high speed onto the surface of the product. The abrasive materials are placed in a cyclone dust filter tank, then drawn through the nozzle and directly contact the surface of the workpiece. This process utilizes compressed airflow to remove rust and contaminants from the surface, ensuring effective cleaning and treatment without causing environmental pollution.

Manual Environmental Protection Type Sandblasting Machine

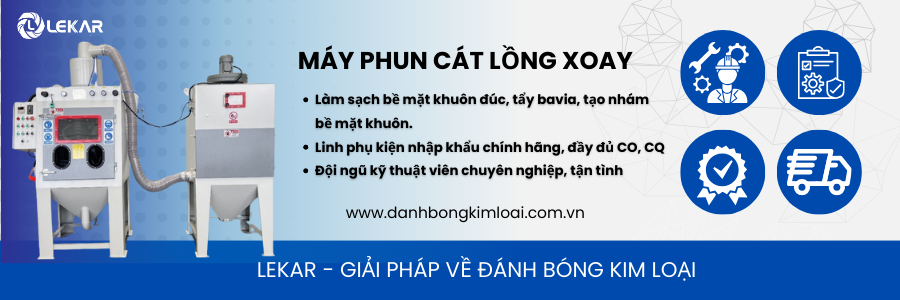

Automatic Drum Type Sand Blasting Machine LKC-1010LD-1.8: This type of machine is specifically designed for surface treatment of small-sized products. It not only focuses on cleaning and improving the surface quality of materials but also minimizes dust emissions during operation, contributing to environmental protection and ensuring worker safety in industrial production facilities.

Automatic Drum Type Sand Blasting Machine LKC-1010LD-1.8:

To ensure a smooth and efficient aluminum surface cleaning process, selecting the right blasting media is extremely important. Currently, the most commonly used abrasive materials include:

- Steel shot

- Steel grit

- Aluminum oxide

- Glass bead

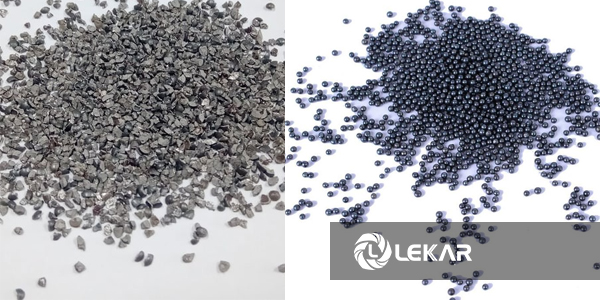

Steel Shot – Steel Grit

When selecting sandblasting media, customers should take note of the following:

– Balance the quantity and frequency of using steel shot and steel grit, as they may cause warping of the surface. These types of abrasive media should only be used for surfaces with thick cross-sections.

– Use aluminum oxide grit to create surface roughness and enhance paint adhesion.

– For applications requiring smooth and glossy finishes, glass beads are the optimal choice.

Aluminum Oxide – Glass Bead

With years of experience in supplying metal surface finishing materials, LEKAR has established itself as a trusted provider of high quality sandblasting media and sandblasting machines, earning the confidence of numerous customers.

At LEKAR, we offer a wide range of blasting abrasives that meet international SAE standards and sand products that comply with FEPA specifications, ensuring absolute reliability and performance.

With a variety of particle sizes and large inventory always available, LEKAR guarantees that customers can easily find products suited to their specific applications. Thanks to their uniform size, high hardness, and low breakage rate, LEKAR’s blasting media deliver efficient and consistent cleaning results.

In particular, our sandblasting and abrasive media are reusable multiple times, helping minimize waste and maximize cost efficiency, all while promoting a cleaner and more sustainable working environment.

Beyond quality products, LEKAR stands out for its dedicated after sales service. Our knowledgeable staff are always ready to assist customers with product selection, technical support, and consultation, ensuring a comprehensive and professional purchasing experience.

For detailed information on aluminum surface cleaning using sandblasting technology, including types of blasting media, sand, and sandblasting machines, please contact LEKAR at the following address:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc, Hanoi. Tel: 0243 7646469

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386

Website: danhbongkimloai.com.vn | lekar.vn