Metal has long been an essential material exploited and utilized by humans. In everyday life, it’s common to see metal-made objects such as household items, door locks, sanitary equipment, jewelry, and more. However, have you ever wondered why these objects have such a shiny surface? How do rough metal pieces, after undergoing processing and fabrication, achieve such brightness and smoothness? What are the most common metal polishing methods used today? Let’s explore with LEKAR in the article below.

1. What is Metal Polishing?

Metal polishing is the final stage in the process of manufacturing a metal product. By using hard or soft materials to work on the metal surface, the process results in smooth, shiny, and glossy products.

During the 20th century and the early 21st century, metal polishing was typically done manually. People had to rely solely on physical force, often using sandpaper to rub against rough surfaces to smoothen and refine the product. This manual method was not only time-consuming and labor-intensive but also delivered limited polishing effectiveness

In recent years, however, the metal polishing process has been industrialized. Instead of manual labor, modern machinery has been developed, significantly increasing productivity and improving product quality.

Countries with advanced metal polishing industries include Germany, Japan, Thailand, and China. Following this global trend, Vietnam has also begun adopting both fully automated and semi-automated machinery for metal surface treatment, greatly enhancing productivity and output.

2. Purpose of the Metal Polishing Process: Enhancing the Surface Finish Based on Usage Needs

Most metal products, after being manufactured, often retain a rough appearance with imperfections such as burrs, weld marks, and excess oil from machining or stamping. The metal polishing process was developed precisely to deliver the final flawless finish before these products reach the market.

Thanks to this process, metal products gain a high level of aesthetics, featuring smooth, bright, and glossy surfaces. Consequently, polished metal products not only achieve a higher market value but also become more competitive compared to non-polished products.

3. Steps in the Metal Polishing Process: A Detailed Guide to Polishing Metal Using a Metal Polishing Machin

In a typical metal polishing process, there are three essential sequential steps:

3.1. Step One: Coarse Polishing (Surface Grinding)

After metals are shaped into various forms, they usually still have protrusions, rough textures, or burrs. Some products may even have sharp edges that could pose safety risks to users. Therefore, the first step before polishing is surface grinding.

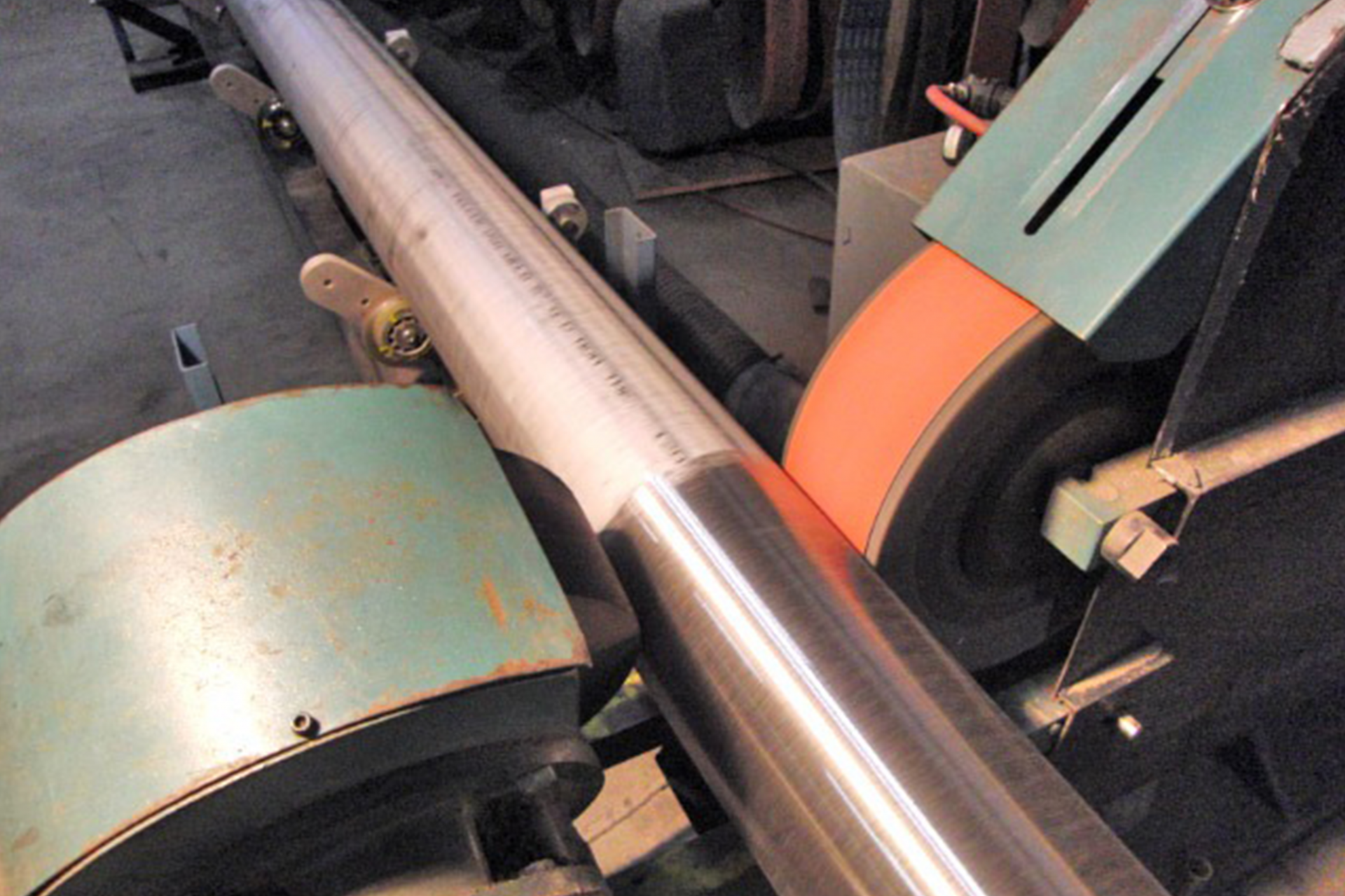

To grind the surface, materials such as grinding stones, abrasive wheels, or coarse sandpaper are commonly used to work on the metal surface. However, using abrasives alone is not highly effective; it must be combined with specialized coarse-cutting polishing compounds (deburring wax) for optimal results.

3.2. Step Two: Intermediate Polishing (Smoothing and Leveling the Surface)

Once the surface has been ground, the metal product already achieves a certain level of flatness and smoothness. At this stage, the operator uses additional materials such as felt buffs, felt wheels, or sisal wheels to further refine and smooth the surface.

Thông thường, bước làm mịn và bước bào mòn sẽ được thực hiện liên tiếp với nhau. Chính vì thế, ở nhiều cơ sở sản xuất, hai bước này sẽ được gộp lại làm một.

3.3. Final Step: Fine Polishing (Brightening and Shining the Surface)

This is the final stage in the metal polishing process. At this step, different types of polishing cloth wheels with varying hardness and softness are attached to polishing machines. These are used in combination with polishing compounds to achieve optimal results.Moreover, these polishing compounds not only enhance the glossiness of the metal surface but also help reduce oxidation over time, keeping the product looking new for longer.

Today, fine polishing is almost entirely performed using modern polishing machines, allowing manufacturers to achieve various levels of shine and brightness according to specific requirements.

The process described above is only a general overview. Depending on the material type, size, and surface finish requirements of each product, the specific polishing procedure may vary. We recommend consulting with experts or professional service providers before carrying out any polishing process to ensure the most suitable and effective approach for your specific metal products.

4. Common Materials and Polishing Compounds Used in Metal Polishing

Currently, the main materials used for metal polishing include grinding stones or polishing media combined with suitable polishing solutions (used in vibratory finishing technology), felt polishing wheels, abrasive wheels, and sandpaper (used in mechanical polishing technology). For fine polishing, polishing compounds can be used along with sisal wheels, soft cloth wheels, or wool felt wheels.

As a leading company with over 15 years of experience in the metal surface finishing industry, LEKAR confidently provides customers with high-quality consumables and chemicals imported from reputable suppliers. We are ready to offer consultation and listen to customers to find the most optimal solution.

Watch the video on polishing compounds here:

Refer to more articles about polishing materials here:

Đá cremic – loại đá được mệnh danh cứng gấp 4 lần thép là gì? Công dụng và thiết bị phù hợp.

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi. Tel: 02437 646469.

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386.

Website: danhbongkimloai.com.vn | lekar.vn