Stainless steel polishing compound (also called polishing wax) is a catalyst applied to a grinding wheel or polishing buff to enhance polishing efficiency. Common types of stainless steel polishing compounds include coarse polishing compound, fine polishing compound, high shine polishing compound, and mirror finish polishing compound.

1. Overview

Stainless steel products, especially decorative items and household goods, increasingly require a high level of shine and precision. Specialized polishing machines such as 3D vibratory finishing machines or vibratory tumblers can achieve a certain degree of surface smoothness but may not meet the highest polishing requirements. For premium products, polishing compounds are typically used in combination with manual polishing techniques to achieve superior finishing quality.

Block or Bar Form

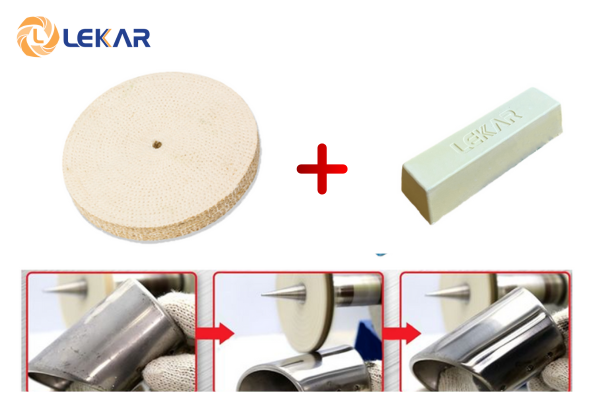

Stainless steel polishing compound, also known as polishing wax, is a catalyst that enhances the brightness or smoothness of stainless steel when processed with a grinding machine. These compounds come in various colors such as green, white, and brown, typically molded into rectangular blocks and wrapped in a protective plastic layer.

In addition to solid block forms, there are also liquid polishing compounds (available in yellow, purple, and brown) designed for use with polishing compound spraying systems. This allows for direct application onto the polishing wheel, making the finishing process more convenient and efficient.

Liquid Polishing Compound

2. Roles

In metal surface treatment, sanding and polishing are crucial steps, especially for decorative equipment, stainless steel furniture, metal products, or any items whose value depends on appearance and aesthetics. The most commonly used tools in surface finishing are grinding machines and polishing additives. Among these additives, polishing compounds play a key role in determining the final quality and value of the product.

3. Types of Stainless Steel Polishing Compounds

Based on their application, polishing compounds are mainly divided into two categories: those used for coarse polishing (surface cutting) and those used for final finishing.

- White polishing compound: Bolt approx, 250g blocks, used for pre-polishing stages.

- Green polishing compound: Suitable for polishing a wide range of materials.

- Brown polishing compound: Used for polishing and pre-polishing both metallic and non-metallic materials (such as plastics).

4. Effective Use of Stainless Steel Polishing Compound

Using polishing compound for metal surface finishing is straightforward. Simply start the grinder or polishing machine, and once the polishing wheel or buffing pad is rotating steadily, press the compound lightly against the spinning surface. This allows the compound to coat the wheel, enabling you to polish and finish the product surface.However, selecting the right polishing compound for a specific material and desired finish is not simple. The choice depends on understanding the chemical properties of the compound, the product’s material, and practical polishing experience.

Notes for Using Stainless Steel Polishing Compound with a Grinding Wheel:

- Use only a moderate amount of compound to avoid waste and ensure even polishing.

- Ensure the wheel’s locking nut is tightened securely to prevent the wheel from stopping during polishing.

- Apply the compound to the grinding wheel while the machine is running and the wheel is rotating.

- Wear protective gloves during operation, as the polishing process generates heat that can cause burns.

Watch the video demonstration of stainless steel polishing using polishing compound:

Contact us:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi. Tel: 02437 646469.

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386.

Website: danhbongkimloai.com.vn | lekar.vn