Polishing compound, also known as buffing wax, polishing wax, or polishing chalk, is an auxiliary material used in the metal surface finishing process.It is categorized into coarse, medium, and fine compounds, each designed to match specific abrasive materials and polishing stages, ensuring the right level of material removal, smoothing, or final high-gloss finishing for different metals.

1. What is Polishing Compound and Its Uses?

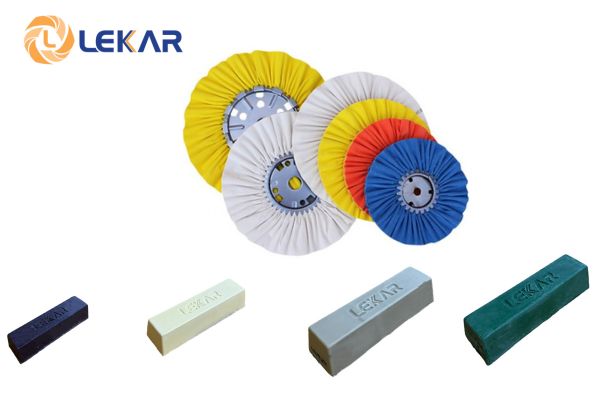

Polishing compound is a catalytic mixture used during the polishing process by applying friction directly onto abrasive wheels such as sanding discs, grinding wheels, buffing wheels, coconut fiber wheels, or cloth wheels. The compound is typically molded into rectangular bars and wrapped in plastic film. Its surface feels slightly sticky to the touch and is odorless. The main purpose of polishing compound is to grind and smooth the surface of metal or non-metal workpieces, producing a smooth and glossy finish according to customer requirements.

Polishing compound is an auxiliary material used in combination with mechanical polishing processes.

A typical metal polishing process consists of three basic steps: rough polishing to remove surface imperfections smoothing to eliminate coarse scratches and level the surface and finally polishing to finish the surface Polishing compound is used primarily in the third stage often combined with coconut fiber wheels or cloth wheels

Polishing compound belongs to the category of auxiliary materials in manual mechanical polishing which is a more hands-on process compared to semi-automatic vibratory polishing machines Metal surfaces requiring a high-gloss finish that cannot be achieved by vibratory polishing are typically finished manually using polishing compound

2. Liệt kê các dạng lơ đánh bóng kim loại điển hình

Typical forms of polishing compound include two main types each suited for different polishing purposes Rectangular polishing bars are applied to manual grinding wheels while liquid polishing wax developed from solid polishing bars is used with automatic grinding machines

Each type of polishing compound is suitable for a corresponding type of abrasive material.

Depending on the type of polishing wheel, the appropriate polishing compound must be selected. Polishing compounds are generally divided into the following basic types:

Coarse polishing compound: Used with abrasive wheels and buffing wheels, mainly for rough surface removal. Applying coarse compound to abrasive, sanding, or buffing wheels reduces cutting friction and creates brightness on the metal surface.

Medium polishing compound: White in color, used with coconut fiber wheels, for semi-fine polishing, helping the metal surface achieve a medium shine.

Fine polishing compound: Green in color, used with cloth polishing wheels, helps achieve a perfect mirror finish on metal surfaces. This fine compound is used in the final stage of metal surface finishing.

3. Instructions for Effective Use of Metal Polishing Compound

Polishing compound is molded, pressed, and cut into shaped bars, making it easy to use with abrasive wheels, buffing wheels, or cloth wheels (abrasive materials). To use the polishing compound, first turn on the grinding machine and wait for the abrasive wheel or polishing pad to reach a stable rotation speed. Then, press the rectangular polishing compound bar against the surface of the abrasive wheel or polishing pad.The compound will melt from the friction heat and adhere to the abrasive surface, allowing you to proceed with polishing the metal product’s surface effectively.

Polishing compound is used together with cloth wheels and felt wheels for manual polishing.

The process of using polishing compound is quite simple, but it is important to keep in mind the following points:

- Do not apply the polishing compound onto the grinding wheel right at the start; let the machine run for a while before bringing the compound into contact with the spinning wheel surface.

- Ensure the grinding wheel is tightly secured with its fastening bolt to prevent the wheel from stopping due to loosening during the polishing process.

- Calculate the appropriate amount of polishing compound based on the surface area of the product to avoid wasting compound and hindering the polishing work.

- Workers performing manual polishing with polishing compound should wear specialized gloves to protect their hands from burns.

For more details about polishing compound products or metal polishing services, please contact:

LEKA POLISHING TECHNOLOGY JOINT STOCK COMPANY – LEKAR GROUP

Head Office: No. 11, Louis VII Street, Louis City Urban Area, Dai Mo Ward, Hanoi.

Northern Branch: Lai Xa Industrial Cluster, Hoai Duc District, Hanoi. Tel: 02437 646469.

Southern Branch: Nam Tan Uyen Industrial Park, Tan Hiep Ward, Ho Chi Minh City. Tel: 02873 033386.

Website: danhbongkimloai.com.vn | lekar.vn